A bike drivetrain is the core mechanical system that transfers power from the rider’s pedaling motion to the rear wheel, enabling forward movement and speed control. Consisting of key components such as the chain, chainrings, cassette, crankset, derailleurs, jockey wheels, and bottom bracket, the drivetrain plays a critical role in efficiency, gear-shifting performance, and overall riding experience across different cycling disciplines, including road, mountain, gravel, and commuter bikes. The evolution of drivetrain technology dates back to the late 19th century, with the first chain-driven safety bicycles, eventually leading to modern 1x, 2x, and electronic shifting systems from brands like Shimano, SRAM, and Campagnolo. Standard drivetrain configurations range from single-speed to 12-speed setups, utilizing materials such as steel, aluminum, titanium, and carbon fiber for optimal strength, durability, and weight reduction. Proper drivetrain maintenance, including regular cleaning, lubrication, and component inspection, ensures smooth gear changes, reduced wear, and maximized pedaling efficiency, making it essential for both casual riders and competitive cyclists seeking peak performance.

This article explores the bike drivetrain system, its definition, different types, and essential maintenance practices, helping cyclists understand how gearing, power transfer, and component care impact riding performance and efficiency.

Table of Contents

What is a drivetrain on a bike?

A drivetrain on a bike is the mechanical system that transfers power from the rider’s pedaling motion to the rear wheel, enabling propulsion, speed control, and efficient gear shifting. The first chain-driven bicycle drivetrain, known as the “safety bicycle,” was introduced in 1885 by John Kemp Starley in England, revolutionizing cycling by replacing direct-drive penny-farthings with a chain-and-sprocket system. Over time, drivetrain technology evolved from single-speed configurations to multi-gear systems, with the introduction of derailleur gears in the early 20th century by brands like Campagnolo (Italy) and later advancements by Shimano (Japan) and SRAM (USA). Modern drivetrains now feature lightweight materials such as carbon fiber, titanium, and aluminum, with advanced 1x and 2x setups, electronic shifting (Di2, AXS, EPS), and optimized gear ratios for both casual riders and elite racers. In everyday biking, a drivetrain ensures smooth pedaling, efficient power transfer, and comfortable gear changes, while in professional road racing, mountain biking, and time trials, it plays a crucial role in aerodynamics, acceleration, and endurance efficiency.

How does a bike drivetrain work?

A bike drivetrain works by converting the rider’s pedaling force into rotational energy, transmitting it through the crankset, chainrings, chain, cassette, and rear wheel to create forward motion. When the rider applies torque to the crank arms, the chain transfers this mechanical energy across the gearing system, adjusting the output force based on the selected gear ratio. The front and rear derailleurs shift the chain between different chainrings and cassette sprockets, altering the mechanical advantage (gear ratio) to optimize pedaling efficiency for acceleration, climbing, or maintaining speed. By leveraging momentum, cadence efficiency, and power distribution, the drivetrain ensures smooth propulsion, controlled deceleration, and optimal energy conservation across varying terrains, from steep inclines to high-speed sprints.

How efficient is the bike drivetrain?

The bike drivetrain operates with an efficiency range of approximately 95% to 98%, depending on factors such as drivetrain cleanliness, lubrication, chainline alignment, and gear selection. In an ideal, well-maintained drivetrain, power transfer losses are minimal, with only 2-5% of energy dissipated due to chain friction, derailleur movement, and bearing resistance. The highest efficiency occurs in a straight chainline with larger chainrings and middle cassette cogs, as this minimizes cross-chaining and excessive articulation of the chain. However, efficiency decreases when the drivetrain is dirty, poorly lubricated, or misaligned, leading to higher friction, chain wear, and power loss. Compared to other mechanical transmission systems, the bicycle drivetrain is one of the most efficient human-powered propulsion mechanisms, ensuring optimal energy transfer for both casual riders and competitive cyclists.

What parts are in a bike’s drivetrain?

In a bike’s drivetrain, the key components include the crankset, chainrings, cranks, bottom bracket, front derailleur, rear derailleur, cassette, and chain, all working together to transfer the rider’s pedaling power to the rear wheel. These bike parts function as a mechanical system that converts torque into forward motion, optimizes gear ratios for different terrains, and ensures smooth power delivery with minimal energy loss. Together, these drivetrain components ensure seamless energy transfer, optimal pedaling efficiency, and reliable shifting performance, making them essential for both casual riders and competitive cyclists.

- Crankset: The main power-transmitting component, consisting of cranks and chainrings, which rotates when the rider pedals, driving the chain to propel the bike forward.

- Chainrings: Circular-toothed rings attached to the crankset that engage with the chain, determining gear ratios and affecting cadence, acceleration, and climbing efficiency.

- Cranks: Lever arms connected to the pedals and crankset, transmitting the rider’s pedaling force into rotational motion, generating mechanical energy for propulsion.

- Bottom Bracket: A sealed bearing system housed inside the bike frame, supporting the crankset and allowing it to spin smoothly with minimal friction and energy loss.

- Front Derailleur: A mechanical or electronic shifting component that moves the chain between different chainrings, enabling gear changes for efficient pedaling.

- Rear Derailleur: A spring-loaded shifting mechanism that guides the chain across the cassette sprockets, controlling gear selection and tension for smooth shifting.

- Cassette: A cluster of sprockets (gears) mounted on the rear wheel hub, working in combination with the chainrings to provide varied gear ratios for speed, climbing, and descending.

- Chain: A flexible, high-tensile metal link system that connects the chainrings to the cassette, transmitting power while ensuring efficient motion and smooth gear transitions.

What is the difference between a bike drivetrain and a groupset?

The difference between a bike drivetrain and a groupset is that the drivetrain specifically refers to the components responsible for transferring pedaling power to the rear wheel, while the groupset includes the entire collection of mechanical or electronic components that control shifting and braking. The drivetrain consists of the crankset, chainrings, bottom bracket, cassette, chain, and derailleurs, whereas a groupset includes all drivetrain components plus brake levers, shifters, calipers, and sometimes even cables or electronic wiring.

This distinction exists because while the drivetrain solely focuses on power transmission and gear changes, the groupset encompasses the full system that controls both shifting and braking, making it a more comprehensive term used by manufacturers like Shimano, SRAM, and Campagnolo. Many cyclists find the terms confusing, as groupsets always include drivetrain parts, but not all drivetrain components (such as chains and cassettes) are necessarily tied to a specific groupset since they can be mixed and matched between different models.

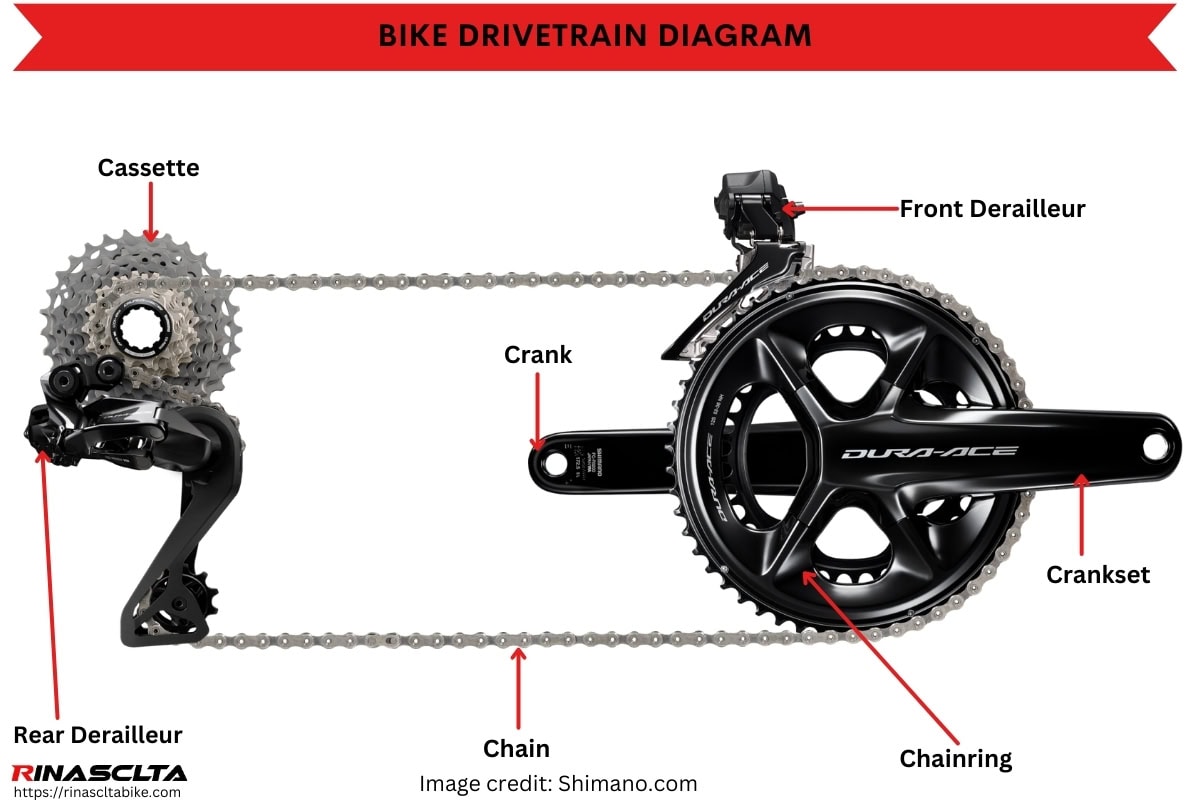

Bike drivetrain diagram

The bike drivetrain diagram below visually illustrates the interconnected components that transfer power from the rider’s pedaling motion to the rear wheel, enabling propulsion and efficient gear shifting. By breaking down key elements such as the crankset, chainrings, chain, cassette, derailleurs, and bottom bracket, the diagram helps cyclists understand how each part functions within the system, how gear ratios impact performance, and how drivetrain maintenance affects efficiency and longevity. This visual reference is essential for beginners learning bike mechanics, riders upgrading components, and mechanics troubleshooting drivetrain issues.

Does a bike drivetrain include a chain?

Yes, a bike drivetrain includes a chain because the chain is a fundamental part of the bike drivetrain, responsible for transmitting power from the chainrings to the cassette, enabling propulsion and gear shifting. The drivetrain consists of all the components that transfer pedaling force to the rear wheel, and the chain serves as the direct link between the front (crankset) and rear (cassette) gearing systems. Power transfer would not be possible without a chain in traditional chain-driven bicycles, making it an essential component for efficiency, smooth shifting, and overall drivetrain functionality.

What are the types of bike drivetrain?

The types of bike drivetrain are categorized based on bike type, chainring configuration, and cassette speed, each designed to optimize performance for specific riding disciplines. By bike type, drivetrains can be mechanical or wireless electronic, commonly found on mountain bikes, road bikes, gravel bikes, cyclocross, fat bikes, e-bikes, fixies, and commuter bikes, each tailored for terrain, durability, and shifting precision. Based on chainring setup, drivetrains are classified as 1x (single chainring), 2x (double chainring), or 3x (triple chainring), affecting gear range, simplicity, and weight. Lastly, drivetrains differ by cassette speed, ranging from 8-speed to 13-speed, with higher-speed cassettes offering smoother gear progression, better cadence control, and improved efficiency in racing or technical terrain.

Drivetrain based on bike types

Bike drivetrain systems vary across mountain bikes, road bikes, gravel bikes, cyclocross bikes, fat bikes, e-bikes, fixies, and commuter bikes, each designed for specific riding conditions, gear range, and performance needs. These differences arise from terrain demands, gearing efficiency, weight considerations, and the need for durability or simplicity. For example, mountain bike drivetrains prioritize wide gear ratios and durability for off-road terrain, while road bike drivetrains focus on efficiency, lightweight components, and smooth high-speed shifting. Below is a comparison of how drivetrain characteristics differ across bike types.

| Bike Type | Drivetrain Type | Gearing System | Common Cassette Speed | Best For |

| Mountain Bike (MTB) | Mechanical or electronic | 1x (most common), 2x (some models) | 10, 11, 12, 13-speed | Technical trails, climbs, and descents with a focus on durability |

| Road Bike | Mechanical or electronic | 2x (most common), 1x (aero/TT models) | 10, 11, 12, 13-speed | High-speed efficiency, endurance, and racing |

| Gravel Bike | Mechanical or electronic | 1x (most common), 2x (for varied terrain) | 10, 11, 12-speed | Mixed terrain, long-distance adventure riding |

| Cyclocross Bike | Mechanical or electronic | 1x (most common), 2x (some models) | 10, 11, 12-speed | Fast off-road racing, quick gear changes in muddy conditions |

| Fat Bike | Mechanical | 1x (most common), 2x (older models) | 8, 9, 10, 11-speed | Snow, sand, and extreme terrain with wide-range gearing |

| E-Bike | Mechanical or electronic (with motor-assist integration) | 1x (most common), 2x (some models) | 8, 9, 10, 11-speed | Assisted pedaling with torque-based shifting |

| Fixie (Fixed Gear) | Single-speed | 1x | Single-speed | Urban riding, simplicity, track racing |

| Commuter Bike | Mechanical (some hub gears) | 1x (most common), Internal hub gears | 3, 5, 7, 8-speed (hub), 8, 9, 10-speed (external) | Urban commuting, reliability, and low maintenance |

Mountain bike drivetrain comparison

Mountain bike drivetrain systems vary based on gear range, chainring configuration, and cassette size, designed to optimize performance across different terrains, climbing efficiency, and descending control. Modern mountain bikes typically use 1x (single chainring) drivetrains for simplicity, reduced weight, and better chain retention, while 2x setups offer a wider range for endurance and touring riders. Cassette sizes have evolved to provide progressive gear steps, with 10-speed to 13-speed cassettes, allowing riders to maintain optimal cadence in steep climbs and fast descents. Below is a comparison of common mountain bike drivetrain setups and their characteristics.

| Mountain Bike Drivetrain Type | Chainring Setup | Common Cassette Size | Best For | Pros | Cons |

| 1×10 | 32T | 11-42T | Entry-level MTB, lightweight XC | Simple, low maintenance, no front derailleur | Limited gear range, harder on steep climbs |

| 1×11 | 30T or 32T | 10-42T / 11-46T | Trail riding, XC racing | Good balance of weight, simplicity, and range | Less top-end speed compared to 2x setups |

| 1×12 | 30T or 32T | 10-50T / 10-52T | All-mountain, enduro, aggressive trail | Widest gear range, lightweight, efficient | More expensive components, requires precise setup |

| 1×13 | 30T or 32T | 10-52T | High-performance enduro, aggressive XC | Best gear range, optimized efficiency | High cost, compatibility issues |

| 2×10 | 24/36T | 11-36T | Touring, long-distance MTB | Wide gear range, better for long climbs | Heavier, requires front derailleur maintenance |

| 2×11 | 26/36T | 11-42T | Marathon MTB, bikepacking | Balanced range, more efficient on mixed terrain | Complex shifting, additional weight |

Drivetrain based on the chainring setting

Bike drivetrain systems are classified based on chainring settings into 1x (single chainring), 2x (double chainring), and 3x (triple chainring) setups, each offering distinct advantages in gear range, weight, and efficiency. These differences arise because 1x drivetrains prioritize simplicity and weight savings, while 2x and 3x setups provide a broader gear range for steep climbs and high-speed riding. Modern mountain bikes, gravel bikes, and some road bikes favor 1x drivetrains for reduced maintenance, whereas touring and endurance cyclists still prefer 2x or 3x setups for long-distance adaptability. Below is a comparison of drivetrain types based on chainring configuration.

| Drivetrain Type | Number of Chainrings | Common Cassette Size | Best For | Pros | Cons |

| 1x Drivetrain | 1 (Single Chainring) | 10-42T / 10-50T / 10-52T | Mountain biking, gravel, cyclocross, road aero | Lightweight, simple, fewer mechanical issues | Smaller gear range, higher cadence variation |

| 2x Drivetrain | 2 (Double Chainring) | 11-32T / 11-34T / 11-36T | Road cycling, touring, endurance MTB | Balanced gear range, efficient for mixed terrain | Heavier, requires front derailleur maintenance |

| 3x Drivetrain | 3 (Triple Chainring) | 11-32T / 11-36T | Touring, heavy-load cycling, older mountain bikes | Widest gear range, excellent for steep climbs | The heaviest, most complex shifting, requires frequent maintenance |

1x vs 2x drivetrain mountain bike

A 1x drivetrain is the preferred choice for modern mountain bikes because it offers simpler shifting, lighter weight, and better chain retention on rough terrain, making it ideal for aggressive trail riding, enduro, and downhill disciplines. A 2x drivetrain, while providing a wider gear range and better cadence control on long climbs, adds extra weight, requires more maintenance, and increases the risk of chain drops, making it less popular in technical off-road riding.

1x vs 3x drivetrain mountain bike

A 1x drivetrain is superior to a 3x setup in mountain biking due to its mechanical simplicity, reduced maintenance, and lighter weight, while still offering enough gear range for most trail conditions. A 3x drivetrain, though providing the widest range of gears for extreme climbing and loaded touring, is heavier, more prone to chain drops, and requires more frequent front derailleur adjustments, making it outdated for modern MTB riding.

1x or 2x drivetrain gravel bike

A 1x drivetrain is ideal for gravel bikes tackling technical, off-road conditions, as it reduces weight, simplifies shifting, and improves durability in muddy or bumpy terrain. However, a 2x drivetrain is better suited for gravel riders who prioritize long-distance efficiency, smoother cadence, and high-speed performance on mixed terrain, as it provides more gear options for both steep climbs and fast descents.

1x or 2x drivetrain bikepacking

A 1x drivetrain is the best option for bikepacking when riding on rugged, unpredictable terrain, as it eliminates front derailleur complexity, reduces mechanical issues, and allows for better reliability during long-distance, unsupported adventures. On the other hand, a 2x drivetrain is preferred for riders covering extended road sections or heavily loaded bikepacking routes, as the extra gear range helps maintain an efficient cadence and reduces fatigue over long climbs.

1x vs 2x drivetrain road bike

A 2x drivetrain is the industry standard for road bikes because it offers smoother gear progression, better cadence optimization, and a wider range for high-speed efficiency and sustained climbing. While a 1x drivetrain reduces weight and simplifies shifting, it sacrifices fine-tuned cadence control and top-end speed, making it less practical for road racing and endurance cycling where maintaining consistent power output is crucial.

What are the differences between road and mountain bike drivetrain?

The differences between road and mountain bike drivetrains include gear range, chainring configuration, cassette size, derailleur design, shifting mechanism, chain design, and durability, as each system is optimized for its specific terrain and riding style. These differences ensure that each drivetrain is optimized for its respective riding conditions, providing maximum efficiency, durability, and performance on the road or trail.

- Gear Range: Road bike drivetrains have tighter gear ratios for smoother cadence control at high speeds, while mountain bike drivetrains use a wider range to handle steep climbs and technical descents.

- Chainring Configuration: Road bikes typically use 2x (compact or standard) setups for efficiency and speed, whereas mountain bikes favor 1x setups to simplify shifting and improve chain retention on rough terrain.

- Cassette Size: Mountain bike cassettes have larger sprockets (up to 52T) for low gearing in steep climbs, while road bike cassettes are smaller (up to 34T) to maintain consistent power output at higher speeds.

- Derailleur Design: Mountain bike derailleurs feature clutch mechanisms to prevent chain slap and drops on rough trails, whereas road bike derailleurs focus on precise, smooth shifting with tighter chain tension.

- Shifting Mechanism: Road bikes use STI (Shimano) or DoubleTap (SRAM) integrated shifters for seamless gear changes, while mountain bikes use trigger shifters or electronic wireless shifting for off-road precision.

- Chain Design: Mountain bike chains are designed for durability and mud-shedding with stronger side plates, while road bike chains prioritize weight savings and smoother engagement for high-cadence pedaling.

- Durability: Mountain bike drivetrains are built to withstand dirt, mud, and impacts, while road drivetrains focus on lightweight construction and aerodynamic efficiency.

Drivetrain based on cassette setting

Bike drivetrain systems are classified based on cassette speeds into 8-speed, 9-speed, 10-speed, 11-speed, 12-speed, and 13-speed setups, each offering different levels of gear range, shifting precision, and compatibility. The number of cassette speeds refers to the total number of sprockets (gears) on the rear wheel, affecting gear progression, smoothness of shifting, and drivetrain efficiency. Lower-speed cassettes (8-speed, 9-speed) are commonly found on entry-level and commuter bikes, offering durability and affordability, while higher-speed cassettes (11-speed, 12-speed, 13-speed) are used in high-performance road, mountain, and gravel bikes, providing smoother gear transitions, better cadence control, and a wider gear range. Below is a comparison of drivetrain types based on cassette speed。

| Drivetrain Type | Number of Gears | Common Cassette Size | Best For | Pros | Cons |

| 8-Speed Drivetrain | 8 | 11-30T / 11-34T | Entry-level MTB, commuting, hybrid bikes | Durable, affordable, easy maintenance | Larger gear jumps, less precise shifting |

| 9-Speed Drivetrain | 9 | 11-34T / 11-36T | Budget MTB, touring, city bikes | Better gear range than 8-speed, still affordable | Heavier than higher-speed setups |

| 10-Speed Drivetrain | 10 | 11-36T / 11-42T | Recreational MTB, gravel, endurance road bikes | Improved shifting smoothness, wider range | Still larger gear gaps compared to 11/12-speed |

| 11-Speed Drivetrain | 11 | 11-28T / 11-34T / 10-42T | Performance road, gravel, and MTB | Better cadence control, smoother shifting | More expensive, requires narrower chain |

| 12-Speed Drivetrain | 12 | 10-50T / 10-52T | High-end MTB, road racing, gravel | Widest gear range, excellent efficiency | Higher cost, requires precise setup |

| 13-Speed Drivetrain | 13 | 10-52T / 9-42T | Ultra-high-performance road, gravel, MTB | Smoothest gear progression, optimized efficiency | Very expensive, limited compatibility |

Are there 2 x 12 bike drivetrains?

Yes, there are 2×12 bike drivetrains because modern road, gravel, and mountain biking demand a wider gear range with smoother shifting, improved cadence control, and enhanced efficiency. Shimano, SRAM, and Campagnolo offer 2×12 drivetrains in their high-end groupsets, such as Shimano Dura-Ace R9200, Ultegra R8100, SRAM Red eTap AXS, and Campagnolo Super Record 12-speed. These drivetrains provide 24 total gear combinations, allowing riders to maintain optimal pedaling efficiency across varying terrains, from steep climbs to high-speed descents. 2×12 setups are commonly used in road racing, endurance cycling, and high-performance gravel riding, where precise gear steps and a broad range are crucial for maintaining power output and reducing fatigue over long distances.

How do you maintain a bike drivetrain?

You can maintain a bike drivetrain by regularly cleaning the chain, lubricating moving parts, inspecting for wear, adjusting derailleurs, checking cassette and chainring condition, and replacing worn components when necessary. Proper maintenance ensures smooth shifting, reduces friction, extends component lifespan, and improves overall riding efficiency. Regular drivetrain maintenance prevents premature wear, improves performance, and ensures a smoother, quieter, and more efficient ride.

- Clean the Chain: Use a chain degreaser and a brush or chain cleaning tool to remove dirt, grime, and old lubricant, preventing excess wear on drivetrain components.

- Lubricate Moving Parts: Apply bike-specific chain lube (wet or dry, depending on riding conditions) to the chain, derailleur pivots, and jockey wheels to reduce friction and ensure smooth operation.

- Inspect for Chain Wear: Use a chain wear checker tool to measure stretch; replace the chain if wear exceeds 0.5% for road bikes or 0.75% for mountain bikes to prevent cassette damage.

- Check Cassette and Chainrings: Examine the teeth for signs of wear, shark-fin shaping, or skipping under load; replace if shifting feels rough or inconsistent.

- Adjust Derailleurs: Fine-tune the limit screws and indexing on front and rear derailleurs using a Phillips screwdriver or hex key to ensure precise and crisp gear shifting.

- Inspect Bottom Bracket and Crankset: Check for play or creaking noises, which may indicate the need for bearing lubrication or replacement to maintain pedaling efficiency.

- Tighten Bolts and Check Cable Tension: Use a torque wrench to secure crankset bolts, derailleur mounts, and chainring bolts while ensuring gear cables are properly tensioned for responsive shifting.

- Replace Worn Components: If shifting performance declines despite adjustments, consider replacing the chain, cassette, chainrings, or derailleur jockey wheels to restore drivetrain efficiency.

How do you service bike chains?

You can service a bike chain by cleaning it with a chain degreaser, chain cleaning tool or brush, and a rag, then dry it completely before applying a suitable lubricant (wet lube for wet conditions, dry lube for dry conditions, or ceramic lube for high performance), ensuring even coverage while wiping off excess to prevent dirt buildup, and finally checking for wear using a chain wear checker tool, replacing the chain if stretch exceeds 0.5% for road bikes or 0.75% for mountain bikes to maintain drivetrain efficiency and prevent premature cassette wear.

How do you change or repair a bike chain?

You can change or repair a bike chain by first shifting to the smallest chainring and cassette cog, then using a chain breaker tool to remove the old chain, measuring the new chain to the correct length by aligning it with the old one (or wrapping it around the largest chainring and cassette cog plus one full link), installing the new chain by threading it through the derailleur jockey wheels, connecting it using a quick link or chain pin, and securing it with quick-link pliers or a chain tool, followed by testing the drivetrain for smooth shifting and applying bike-specific chain lubricant to ensure optimal performance and longevity.

How do you service bike cranksets?

You can service a bike crankset by first removing the crank arms using a hex key or crank puller tool (depending on the crankset type), then inspecting the chainrings for wear, bolt tightness, and alignment, cleaning the entire crankset with degreaser and a brush, checking the bottom bracket bearings for smooth rotation and play, applying grease or anti-seize compound on the spindle and threads to prevent creaking, reinstalling the crank arms to the correct torque specification using a torque wrench, and finally testing for proper alignment and smooth pedaling before applying chain lubricant for optimal drivetrain efficiency.

How do you replace a 2-piece crankset?

You can replace a 2-piece crankset by first loosening the pinch bolts on the non-drive side crank arm using a hex key, removing the preload cap with a bottom bracket preload tool, then sliding the crank spindle out of the bottom bracket, cleaning and inspecting the bottom bracket bearings for wear, applying grease or anti-seize compound to the spindle, inserting the new crankset through the bottom bracket, reattaching the non-drive side crank arm, tightening the preload cap, and torquing the pinch bolts to the manufacturer’s specification using a torque wrench before checking for smooth rotation.

How do you change your bike chainrings?

You can change your bike chainrings by first removing the crankset using a hex key or crank puller tool, securing the chainring bolts with a chainring bolt wrench, loosening them with a Torx or hex key, swapping out the old chainring for the new one while ensuring the correct tooth count and alignment, tightening the bolts evenly to the specified torque, reinstalling the crankset, and testing the drivetrain for proper chain engagement before applying bike-specific lubricant for smooth operation.

How do you check your front derailleur?

You can check your front derailleur by visually inspecting its alignment relative to the chainrings, ensuring the cage is parallel to the chainrings and positioned 1-3mm above the largest chainring, then shifting through the gears while checking for rubbing or hesitation, adjusting the limit screws (H & L) with a Phillips screwdriver to prevent over-shifting, fine-tuning cable tension with the barrel adjuster, and cleaning the derailleur with degreaser and a brush before lubricating the pivot points to maintain smooth operation.

How do you change a bike cassette?

You can change a bike cassette by first removing the rear wheel, securing the cassette with a chain whip tool, loosening the lockring using a cassette lockring tool and a wrench, sliding off the old cassette, cleaning the freehub with degreaser and a rag, installing the new cassette while aligning the splines, tightening the lockring to the correct torque using a torque wrench, reinstalling the wheel, and testing the shifting to ensure smooth gear engagement.

How do you replace a derailleur hanger?

You can replace a derailleur hanger by shifting to the smallest rear cog, removing the rear derailleur using a hex key, unscrewing the old hanger from the dropout with a Torx or hex key, cleaning the mounting area, installing the new hanger while ensuring proper alignment, securing it to the correct torque, reattaching the derailleur, adjusting the derailleur position using the limit screws and barrel adjuster, and testing shifting for smooth operation.

How do you clean the bike drivetrain?

You can clean the bike drivetrain by applying a chain degreaser to the chain, cassette, and chainrings, scrubbing them with a drivetrain cleaning brush or chain cleaning tool, wiping off excess grime with a rag, rinsing with water if necessary, drying completely, applying bike-specific lubricant to the chain while wiping off excess to prevent dirt buildup, and checking for any worn components that may need replacement.

How often should you clean/lubricate a bike drivetrain?

You should clean and lubricate your bike drivetrain every 100-200 km (60-120 miles) for road cycling and every 50-100 km (30-60 miles) for mountain biking or gravel riding, or at least once a week for frequent riders and monthly for occasional cyclists, as dirt, grime, and moisture buildup can accelerate chain wear, increase friction, reduce shifting efficiency, and lead to premature drivetrain component failure, especially in wet or dusty conditions.

What does a drivetrain cost?

A drivetrain cost varies depending on the components, brand, and performance level, typically ranging from US $150-$300 (€140-€280 / £120-£250) for entry-level setups, US $400-$900 (€370-€850 / £330-£750) for mid-range groupsets, and US $1,000-$2,500+ (€930-€2,300+ / £850-£2,100+) for high-performance or electronic drivetrains. Affordable drivetrains like Shimano Tourney, SRAM SX Eagle, and Microshift Advent are suited for budget bikes, while Shimano 105, GRX, and SRAM Rival dominate the mid-tier range for road and gravel. High-end groupsets such as Shimano Dura-Ace Di2, SRAM Red eTap AXS, and Campagnolo Super Record EPS feature wireless shifting, lightweight materials (carbon, titanium), and precise performance, making them the choice for elite racers and serious cyclists. Individual drivetrain components—like chains (US $20-$80), cassettes (US $50-$400), and derailleurs (US $50-$700)—can be replaced separately, allowing riders to upgrade or maintain their drivetrain cost-effectively.

How does a drivetrain wear out?

A bike drivetrain wears out due to continuous friction, dirt accumulation, chain stretch, and mechanical stress from shifting under load, causing gradual degradation of key components over time. The chain is the first component to wear out, as it experiences constant movement and contact with the chainrings and cassette, leading to elongation (stretch) and reduced engagement with the teeth, accelerating wear on the entire system. The cassette and chainrings wear down as their teeth become hooked or worn flat, resulting in poor shifting and chain slippage. The jockey wheels in the rear derailleur also degrade due to high-speed rotation and dirt buildup. Harder-wearing components include the crank arms and bottom bracket, which, while subject to wear, typically last much longer due to their robust materials and sealed bearing systems. Regular cleaning, lubrication, and timely chain replacement (every 2,000-4,000 km / 1,200-2,500 miles) help slow drivetrain wear and extend the lifespan of all components.

How long should a drivetrain last?

A drivetrain should last between 5,000 to 15,000 km (3,000 to 9,000 miles), depending on riding conditions, maintenance frequency, terrain, and component quality. A well-maintained road bike drivetrain can last up to 15,000 km (9,000 miles) due to smoother riding surfaces and less contamination, while mountain bike and gravel drivetrains wear out faster, typically lasting 5,000 to 10,000 km (3,000 to 6,000 miles), due to increased exposure to mud, dust, and shifting under load. The chain is usually the first component to wear out, needing replacement every 2,000-4,000 km (1,200-2,500 miles), while cassettes and chainrings last longer, often two to three chain lifecycles before requiring replacement. Premium drivetrains from Shimano Dura-Ace, SRAM Red AXS, and Campagnolo Super Record tend to last longer due to high-quality materials (titanium, carbon, coated steel), while entry-level drivetrains may wear out faster. Regular cleaning, lubrication, and proper shifting techniques help maximize drivetrain lifespan.

How to make a bike drivetrain last longer?

You can make a bike drivetrain last longer by regularly cleaning the chain every 100-200 km (60-120 miles) for road cycling and every 50-100 km (30-60 miles) for mountain biking, applying the correct wet or dry lubricant, replacing the chain before it reaches** 0.5% wear for road bikes or 0.75% for mountain bikes, avoiding extreme chain angles (cross-chaining), shifting smoothly to reduce stress on the cassette and chainrings, checking derailleur alignment to prevent premature wear, keeping the bottom bracket and crankset properly torqued, and using high-quality components from brands like Shimano, SRAM, or Campagnolo, as premium materials like hardened steel, titanium, and coated chains extend drivetrain durability.

When should I replace my bike drivetrain?

You should replace your bike drivetrain when your chain reaches 0.5% wear for road bikes or 0.75% for mountain bikes (measured with a chain wear tool), typically every 2,000-4,000 km (1,200-2,500 miles), or when shifting becomes inconsistent, the chain skips under load, or the cassette and chainrings show visibly worn or hooked teeth.** If the drivetrain components are not replaced in time, excessive chain wear can damage the cassette and chainrings, requiring a full drivetrain replacement, which can be costlier than regular chain maintenance.

How much does it cost to replace the bike drivetrain?

A drivetrain replacement costs between $150-$300 (€140-€280 / £120-£250) for entry-level setups, $400-$900 (€370-€850 / £330-£750) for mid-range groupsets, and $1,000-$2,500+ (€930-€2,300+ / £850-£2,100+) for high-performance electronic drivetrains. Individual component costs vary, with chains priced at $20-$80 (€18-€75 / £15-£65), cassettes at $50-$400 (€45-€370 / £40-£350), cranksets at $100-$600 (€90-€550 / £85-£500), and derailleurs at $50-$700 (€45-€650 / £40-£600). Labor costs for drivetrain replacement at a bike shop typically range from $50-$150 (€45-€140 / £40-£130) depending on the complexity of the installation, with additional fees for derailleur tuning and bottom bracket servicing. Premium drivetrains from Shimano Dura-Ace Di2, SRAM Red AXS, and Campagnolo Super Record EPS cost more due to lightweight materials (carbon, titanium) and advanced shifting technology.

Can you repair the bike drivetrain?

Yes, you can repair a bike drivetrain because individual components such as the chain, cassette, chainrings, and derailleurs can be replaced separately when worn or damaged, but if multiple components are excessively worn, a full drivetrain replacement may be necessary. Regular maintenance, proper lubrication, and timely chain replacement help extend drivetrain life and reduce the need for costly repairs.

Will off-road trails ruin your bike drivetrain?

Yes, off-road trails can accelerate drivetrain wear because dirt, mud, sand, and water increase friction, leading to faster chain, cassette, and derailleur wear, but regular cleaning, lubrication, and using a durable drivetrain setup designed for off-road riding (like Shimano XT, SRAM GX, or Campagnolo Ekar) can minimize long-term damage. Riders can further protect their drivetrain by avoiding cross-chaining, shifting smoothly, and replacing worn components before they cause damage to the entire system.

Can I upgrade my bike’s drivetrain?

Yes, you can upgrade your bike’s drivetrain because most bikes allow for component swaps, such as upgrading from an 8-speed to an 11-speed or switching from mechanical to electronic shifting, but compatibility with the existing bike frame, freehub body, bottom bracket, and shifters must be checked before upgrading. High-end drivetrains from Shimano, SRAM, and Campagnolo offer smoother shifting, lower weight, and improved efficiency, making upgrades a worthwhile investment for performance-oriented riders.

Bike drivetrain brands and manufacturers

Bike drivetrain brands and manufacturers play a crucial role in cycling performance, offering a range of drivetrain systems tailored for road, mountain, gravel, and commuter bikes. Leading brands such as Shimano, SRAM, and Campagnolo dominate the high-performance market, while Microshift and SunRace provide budget-friendly alternatives with reliable shifting performance. Each bike manufacturer specializes in different technologies, gear systems, and drivetrain innovations, catering to various riding styles and preferences. Below is a comparison of major drivetrain brands and their specialties.

| Bike Drivetrain Brand | Founded | Country/Region | Specialty |

| Shimano | 1921 | Japan | Leader in road, mountain, and gravel drivetrains, known for Dura-Ace, Ultegra, XT, and GRX groupsets. |

| SRAM | 1987 | USA | Pioneer in 1x drivetrains and wireless shifting, known for Red AXS, Force AXS, Eagle, and GX groupsets. |

| Campagnolo | 1933 | Italy | Premium road drivetrains with high-end materials, known for Super Record, Record, and Chorus groupsets. |

| Microshift | 1999 | Taiwan, China | Affordable drivetrain solutions, popular in budget gravel and touring setups. |

| SunRace | 1972 | Taiwan, China | Produces budget cassettes and drivetrains, commonly used in entry-level and hybrid bikes. |

| Box Components | 2012 | USA | Innovative MTB drivetrains, specializing in 1x setups with wide-range cassettes. |

| Rotor | 1994 | Spain | Known for high-end modular cranksets and hydraulic shifting systems. |

| FSA (Full Speed Ahead) | 1993 | Taiwan, China | Develops road and gravel drivetrain components, including the K-Force WE electronic shifting system. |

| TRP (Tektro Racing Products) | 1986 | Taiwan, China | Expanding into drivetrain components, known for derailleur systems in gravel and MTB categories. |

Bike drivetrain Shimano vs Microshift

Bike drivetrains from Shimano and Microshift cater to different market segments, with Shimano dominating the high-performance road, mountain, and gravel cycling world through its advanced technology, premium materials, and refined shifting systems, while Microshift offers budget-friendly alternatives with solid performance, making it a popular choice for entry-level, touring, and commuter bikes.