Bike pumps are essential inflation devices designed to maintain proper air pressure in bicycle tires, ensuring safety, efficiency, and comfort for every ride. Their role is critical because tire pressure directly affects rolling resistance, grip, puncture protection, and overall performance. The history of bike pumps dates back to the late 19th century, when cyclists used simple hand-operated inflators, later evolving into floor pumps, mini pumps, CO₂ inflators, and electronic pumps as tire technology advanced. Many riders struggle to choose the right pump because they must consider valve types (Presta or Schrader), portability, pressure capacity, durability, and accuracy, alongside related terms like PSI, gauge, tubeless setup, and CO₂ cartridges. In essence, a bike pump is more than a convenience—it is a vital tool that preserves the value of the bike and the rider’s independence, making it crucial to understand the different types and how to select the right one for your needs.

This article explains what a bike pump is, outlines the different types available, and provides guidance on how to choose the right one for your cycling needs.

Table of Contents

What is a bike pump?

A bike pump is a device designed to inflate bicycle tires by compressing and transferring air into an inner tube or tubeless setup through a valve, ensuring proper tire pressure for safe and efficient riding. The first bike pumps appeared in the late 19th century in Europe, as pneumatic bicycle tires invented by John Boyd Dunlop in 1888 created the need for a portable inflation tool, initially simple hand-operated cylinders. Over time, pumps evolved into floor pumps, mini pumps, CO₂ inflators, frame-fit pumps, and digital/electric pumps, incorporating features like pressure gauges, dual valve heads (Presta/Schrader), tubeless inflators, and high-pressure chambers. Related terms include PSI, bar, valve compatibility, CO₂ cartridges, and gauge accuracy, all critical in determining a pump’s effectiveness. A bike pump is therefore not just an accessory but a vital maintenance tool that preserves tire performance, reduces rolling resistance, prevents pinch flats, and ultimately protects both the value of the bike and the rider’s safety.

How does a bike pump work?

A bike pump works by using a piston-and-cylinder mechanism to compress air and force it through a hose and valve head into the bicycle tire, increasing internal pressure until the desired PSI or bar is reached. When you pull the handle, the piston draws air into the cylinder; when you push down, the air is compressed and directed through a one-way check valve into the tire. The pump head connects to either a Presta or Schrader valve, ensuring an airtight seal, while some models include dual or switchable heads for compatibility. A built-in pressure gauge measures the air pressure inside the tire, allowing riders to match manufacturer recommendations with accuracy. The efficiency depends on cylinder volume, stroke length, and seal quality, with high-volume pumps filling tires quickly and high-pressure pumps designed for road tires. Overall, the mechanism balances air transfer, volume, and pressure accuracy, making it an essential tool for tire performance, rider safety, and long-term bike maintenance.

How do CO2 bike pumps work?

A CO₂ bike pump works by releasing compressed carbon dioxide from a CO₂ cartridge through a valve-controlled inflator head that attaches to the tire’s Presta or Schrader valve, rapidly filling the tube or tubeless setup with pressurized gas. The mechanism involves puncturing or twisting the cartridge to break a seal or pin, which releases CO₂ into the inflator body; the rider then controls the flow with a trigger or twist valve to prevent overinflation. Some CO₂ pumps include a pressure regulator or gauge for more accurate inflation, though many rely on rider judgment and volume experience. Since cartridges are pre-pressurized, they deliver air much faster than manual pumps, making them ideal for emergency roadside repairs or race situations. However, their limited volume (commonly 16–25g cartridges) means each is single-use, and CO₂ leaks out of tires faster than regular air, so topping up later with a standard pump is recommended.

Who invented bike pumps?

The bike pump was invented in 1887 in France by Etienne Lenoir, who designed the first hand-operated air pump specifically to inflate the newly developed pneumatic bicycle tires that had been popularized by John Boyd Dunlop in 1888. It was created to solve the problem of efficiently maintaining tire pressure, using a piston-and-cylinder mechanism that could transfer compressed air through a valve into the tire. This invention quickly spread across Europe and became a standard tool for cyclists, later evolving into modern designs like floor pumps, frame-fit pumps, mini pumps, and CO₂ inflators to meet the demands of different riding conditions.

Why use a CO2 bike pump?

A CO₂ bike pump is used because it provides fast, compact, and efficient tire inflation, making it ideal for emergencies, racing, or long rides where carrying a full-size pump is impractical. It works with single-use CO₂ cartridges (16–25g) that deliver high-pressure air instantly into Presta or Schrader valves, allowing a road tire to inflate to full pressure in seconds. Related terms include inflator head, regulator, PSI accuracy, cartridge volume, and portability, all of which highlight its value in convenience and speed. While not a replacement for a regular floor pump, a CO₂ pump is a lightweight backup solution that saves time and ensures riders can quickly get back on the road or trail.

Do all bike pumps fit all bikes?

No, all bike pumps do not fit all bikes, because pumps must match the valve type on the tire—most commonly Presta or Schrader, and occasionally Dunlop valves—and not every pump head is compatible with all of them. Some pumps come with dual heads, switchable inserts, or smart valves that automatically adjust, while others are designed for only one valve style. The value of compatibility lies in ensuring airtight sealing, accurate pressure transfer, and gauge reliability, so choosing the right pump for your bike’s valve system is essential for safe and efficient inflation.

What are bike pumps made of?

Bike pumps are typically made of steel, aluminum, plastic, rubber, brass, composite materials, carbon fiber, silicone, and sometimes wood, because each material offers specific benefits in terms of strength, durability, weight, sealing, comfort, or design. These materials are combined to create pumps that are efficient, lightweight, and long-lasting while maintaining accurate pressure delivery.

- Steel parts: Used in pistons and shafts for strength and long-term durability.

- Aluminum parts: Provide a lightweight yet sturdy body for portable pumps.

- Plastic parts: Found in casings, handles, and pump heads for affordability and reduced weight.

- Rubber parts: Used in seals, gaskets, and hoses to maintain airtight compression.

- Brass parts: Common in valve heads and fittings for corrosion resistance and precision.

- Composite materials: Blend strength and lightness, often used in mid- to high-end pump bodies.

- Carbon fiber parts: Applied in premium mini pumps for maximum strength-to-weight performance.

- Silicone parts: Found in grips and protective covers for comfort and flexibility.

- Wood parts: Used in some classic or retro pump handles for aesthetics and ergonomics.

How are bike pumps made?

Bike pumps are made through several steps including design, material selection, machining, molding, assembly, sealing, calibration, quality control, and packaging, because each stage ensures the pump is strong, accurate, durable, and reliable for inflating bike tires. These steps transform raw materials into precise tools capable of maintaining correct tire pressure for safety and performance.

- Design: Engineers create CAD models that define the pump’s dimensions, pressure range, and valve compatibility.

- Material selection: Metals, plastics, and rubbers are chosen for strength, weight, sealing, and durability.

- Machining: Cylinders, pistons, and shafts are cut and shaped to precise tolerances.

- Molding: Plastic and composite parts such as handles, casings, and heads are injection-molded.

- Assembly: Pistons, hoses, gauges, and valve heads are combined into the full pump structure.

- Sealing: Rubber gaskets, O-rings, and washers are installed to create airtight compression.

- Calibration: Pressure gauges are tested and adjusted for accurate PSI/bar readings.

- Quality control: Finished pumps are checked for leaks, durability, and performance consistency.

- Packaging: Pumps are labeled, boxed, and prepared for distribution to shops and riders.

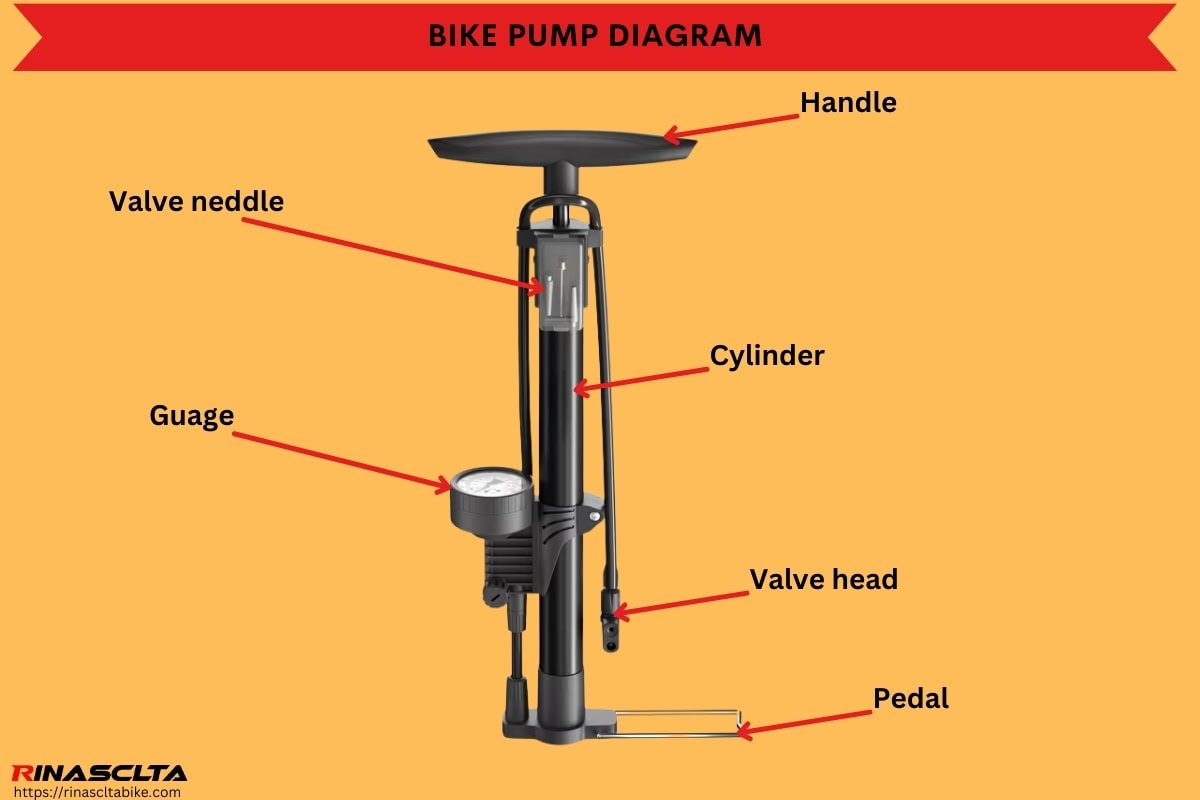

Bike pump diagram

A bike pump diagram is important because it helps riders understand the internal parts, mechanism, and airflow process, making it easier to use, maintain, and troubleshoot their pump.

What are the different types of bike pumps?

The different types of bike pumps can be grouped by design, bike type, and tube type, because each category reflects how pumps are built, what bikes they serve, and the tire systems they support. Pumps by design (floor, hand, CO₂, foot, frame-mounted, suspension shock, electric, morph) focus on function and portability; pumps by bike type (gravel, electric, mountain, road, BMX) address specific pressure and volume needs; and pumps by tube type ensure compatibility with Presta, Schrader, or tubeless systems, giving riders the right balance of accuracy, speed, and convenience for safe and efficient tire inflation.

Bike pump types based on design

Bike pump types based on design include floor pumps, hand pumps, CO₂ pumps, foot pumps, frame-mounted pumps, suspension shock pumps, electric pumps, and morph pumps, because each is built to balance portability, pressure capacity, and convenience depending on where and how the cyclist needs to inflate their tires. These categories exist to match the demands of different riding situations, from at-home workshop use to emergency roadside repairs.

- Floor pump: Large, stable pump with a gauge for quick and accurate inflation at home or in a workshop.

- Hand pump: Compact and portable, ideal for on-the-go inflation but requires more effort.

- CO₂ pump: Uses disposable cartridges for instant inflation, lightweight and fast but single-use.

- Foot pump: Operated with the foot for convenience and stability, often used in home garages.

- Frame-mounted pump: Long pump attached to the bike frame, offering high volume for roadside emergencies.

- Suspension shock pump: Specialized high-pressure pump for adjusting air suspension forks and shocks.

- Electric pump: Battery-powered or rechargeable, delivering precise inflation with minimal effort.

- Morph pump: Hybrid design combining the power of a floor pump with the portability of a hand pump.

Bike pump types based on bike type

Bike pump types based on bike type include gravel, electric, mountain, road, and BMX pumps, because each style of bike requires different pressure ranges, volume capacity, and valve compatibility to match its tire size, riding terrain, and performance needs. This classification ensures riders choose a pump that delivers the right balance of high-pressure accuracy, high-volume output, or durability for their specific bike setup.

- Gravel bike pump: Built to handle medium-volume tires, often with tubeless compatibility and reliable PSI gauges.

- Electric bike pump: Designed for e-bikes, with higher pressure support, digital displays, and portable rechargeable options.

- Mountain bike pump: Prioritizes high-volume output for wide tires and often includes tubeless inflation capability.

- Road bike pump: Focuses on delivering high-pressure inflation (up to 120+ PSI) with precise gauges for narrow tires.

- BMX pump: Compact, durable, and capable of handling lower-pressure but higher-durability tire setups.

Bike pump types based on bike tube valves

Bike pump types based on bike tube valves include Presta, Schrader, Woods (Dunlop), and tubeless pumps, because different valve systems require specific pump heads or adapters to create a proper airtight seal and deliver accurate pressure. This classification ensures cyclists use the right pump for their valve type, preventing leaks, damage, or underinflation while maximizing efficiency and safety.

- Presta valve pump: Designed for narrow, high-pressure valves found on road, gravel, and performance bikes.

- Schrader valve pump: Compatible with wider automotive-style valves, common on mountain, BMX, and casual bikes.

- Woods (Dunlop) valve pump: Supports the less common European-style valve, often used on older city or commuter bikes.

- Tubeless pump: Built with a high-volume chamber or booster system to seat tubeless tires securely on the rim.

Presta valve adapter for bike pump

A Presta valve adapter is a small metal or plastic fitting that allows a bike pump designed for Schrader valves (the same type used on car tires) to inflate a Presta valve, which is narrower and common on road, gravel, and performance bikes. It screws onto the top of the Presta valve after you unscrew the small lock nut, effectively converting it to a Schrader-compatible size so that standard floor pumps, gas station air compressors, or mini pumps can be used. Related terms include valve compatibility, airtight seal, PSI accuracy, and convenience, since the adapter ensures proper inflation without needing a specialized Presta-only pump. Its value lies in being a lightweight, low-cost, and portable solution that gives riders the flexibility to inflate their tires anywhere, especially in emergencies.

Bike pump adapter types

Bike pump adapter types include Presta-to-Schrader, Schrader-to-Presta, Woods (Dunlop) adapters, universal dual adapters, and tubeless inflator adapters, because different bikes and pumps use varying valve standards, and adapters ensure airtight compatibility across all systems. These adapters add versatility, allowing one pump to service multiple valve types or specialized setups.

- Presta-to-Schrader adapter: Converts narrow Presta valves to fit pumps or air compressors designed for Schrader.

- Schrader-to-Presta adapter: Allows a Schrader valve to be inflated with a Presta-only pump head.

- Woods (Dunlop) adapter: Enables inflation of the less common European-style Woods valves with standard pumps.

- Universal dual adapter: Combines Presta and Schrader compatibility in one head, switching automatically or manually.

- Tubeless inflator adapter: Connects a pump or air compressor to tubeless valve stems, often with a booster chamber for seating tires.

How do you choose a bike pump?

You can choose a bike pump by considering valve compatibility, high volume versus high pressure, pump head design, efficiency, price, pump materials, warranty and rebuild kits, gauge design and accuracy, hose length, and size, because each factor affects how well the pump matches your bike type, inflation needs, durability, and convenience. These considerations ensure you select a reliable, accurate, and practical pump for both home use and on-the-go repairs.

- Valve compatibility: Ensures the pump works with your bike’s valve type (Presta, Schrader, Dunlop).

- High volume versus high pressure: Matches pump output to wide MTB/gravel tires (volume) or narrow road tires (pressure).

- Pump head design: Determines ease of attaching to the valve and maintaining an airtight seal.

- Efficiency: Measures how quickly the pump inflates a tire with minimal strokes or effort.

- Price: Balances your budget with pump quality, features, and durability.

- Pump materials: Steel, aluminum, or composites affect strength, weight, and long-term use.

- Warranty and rebuild kits: Provide long-term serviceability and confidence in the product.

- Gauge design and accuracy (floor pumps): Ensures precise pressure readings for performance and safety.

- Hose length (floor pumps): Adds convenience and reach when inflating tires on different bikes.

- Size (mini pumps): Determines portability for road or trail use without adding bulk.

What is a good bike pump?

A good bike pump is one that reliably delivers the right air pressure, volume, and valve compatibility for your bike while being durable, efficient, and easy to use. Key factors include valve type support (Presta, Schrader, Dunlop), pressure range (high-volume vs. high-pressure), gauge accuracy, pump head design, hose length, and portability depending on whether it’s a floor pump, mini pump, CO₂ inflator, or electric pump. Related terms like PSI, bar, tubeless booster, dual head, and rebuild kits highlight the features that separate basic pumps from high-quality ones. Ultimately, a good bike pump is an investment in safety, performance, and convenience, ensuring your tires are always inflated correctly for the best ride quality.

Are CO2 bike pumps any good?

Yes, CO₂ bike pumps are good because they provide fast, lightweight, and compact inflation using cartridges, ideal for racing or emergencies, but they are single-use, less precise, and CO₂ leaks faster than regular air.

Are electric bike pumps good?

Yes, electric bike pumps are good because they offer precise inflation with digital gauges, portability, and minimal effort, but they depend on battery life and are usually bulkier than mini pumps.

Does the pressure gauge matter?

Yes, the pressure gauge matters because it ensures accurate PSI/bar readings to match tire requirements, preventing underinflation (higher rolling resistance) or overinflation (reduced grip, risk of blowouts).

Can a bike pump inflate an air mattress?

Yes, a bike pump can inflate an air mattress because Schrader-compatible pumps or those with adapters can move air into large chambers, but they are slow and inefficient compared to dedicated air mattress pumps.

Can I use a basketball pump on a bike tire?

Yes, you can use a basketball pump on a bike tire if the valve type matches or with a Presta/Schrader adapter, but basketball pumps are low-volume, less durable, and not designed for high PSI.

Can you blow up balloons with a bike pump?

Yes, you can blow up balloons with a bike pump because the pump pushes air into any open chamber, but you may need a nozzle adapter, and it is less practical than a hand balloon pump.

Can you take a bike pump on a plane?

Yes, you can take a bike pump on a plane because manual pumps are allowed in both carry-on and checked luggage, but CO₂ cartridges are prohibited due to pressurization risks.

Do ball pumps work on bikes?

No, ball pumps do not work well on bikes because they are designed for low-pressure, small-volume inflation, and without proper adapters they can’t reach the high PSI needed for bike tires.

Do gas station air pumps work for bikes?

Yes, gas station air pumps work for bikes if the tire has a Schrader valve or a Presta-to-Schrader adapter, but they inflate very quickly and can overinflate or damage bike tubes if not monitored carefully.

Do road bikes need a special pump?

Yes, road bikes need a special pump because they require high-pressure (100–120+ PSI) pumps with Presta valve compatibility, unlike basic pumps made for low-pressure tires.

Do you need a special bike pump for presta valve?

Yes, you need a special bike pump for Presta valves because they are narrower and use a threaded lock nut, but many modern pumps are dual-head or smart-head and work with both Presta and Schrader.

Can I use an air mattress pump for a bike?

No, you cannot use an air mattress pump for a bike because mattress pumps are low-pressure, high-volume, and bike tires need high PSI that those pumps cannot deliver.

Can you use any air pump for bike tires?

No, you cannot use any air pump for bike tires because pumps must match valve type, PSI range, and volume requirements, but with the right adapter and pressure rating, some non-bike pumps may still work.

How do you make a bike pump at home?

You can make a bike pump at home by building a simple piston-and-cylinder system using basic materials like PVC pipe, a rubber seal or gasket, a check valve, and a hose with a Presta/Schrader-compatible head. The mechanism works the same way as a commercial pump: when you pull the piston back, air enters the cylinder; when you push down, the air is compressed and forced through a one-way valve into the tire.

- Cylinder: Cut a section of PVC pipe to act as the air chamber.

- Piston: Fit a smaller rod with a rubber washer or gasket at the end to create an airtight seal inside the pipe.

- Check valve: Install a one-way valve at the pipe’s base to allow air to flow out but not back in.

- Hose: Attach a flexible rubber or plastic hose to the valve outlet.

- Pump head: Fit or adapt a nozzle that seals against Presta or Schrader valves, often using a repurposed old pump head.

- Handle: Add a crosspiece or grip on top of the piston rod for pushing and pulling.

This DIY pump demonstrates the value of airflow mechanics, sealing, and valve compatibility, but it won’t match the durability, PSI accuracy, or portability of professional pumps—so it’s best as an educational project or backup solution.

Do I need a mini bike pump if I have CO2 cartridges?

No, you don’t need a mini bike pump if you have CO₂ cartridges, because the cartridges can fully inflate a tire quickly and are lightweight and portable, making them ideal for emergencies or racing situations. But many cyclists still carry a mini pump as a backup since CO₂ is single-use, leaks out faster than regular air, and cartridges can run out or fail. The value of having both lies in combining speed and convenience (CO₂) with unlimited reliability (mini pump), ensuring you’re never stranded on the road or trail.

How should I carry my mini pump?

You should carry your mini pump in a way that is both secure and accessible, such as mounted to the bike frame with a bracket, tucked into a saddlebag or frame bag, or stored in a jersey pocket or backpack. The choice depends on your riding style: frame mounts keep the pump always ready, bags provide protection from dirt and weather, and jersey pockets offer quick access for road cyclists. Related terms include mounting bracket, Velcro straps, frame compatibility, portability, and weather resistance, all of which add value by ensuring the pump is protected, doesn’t interfere with pedaling, and is available when you need it most.

How do you use a bike pump?

You can use a bike pump by first checking your valve type (Presta, Schrader, or Dunlop) and ensuring the pump head is compatible or fitted with the right adapter. Then, unscrew the valve cap (and the small lock nut for Presta), attach the pump head securely to create an airtight seal, and begin pumping by moving the handle and piston to force air into the tire. If the pump has a gauge, monitor the PSI/bar to match your tire’s recommended pressure, adjusting for road, gravel, or mountain bike needs. Related tools include Presta-Schrader adapters, CO₂ inflators, and torque wrenches (for reinstalling wheels after inflation), which add flexibility and precision. Once done, remove the pump head carefully, tighten the Presta nut if used, and replace the valve cap. This process ensures accurate inflation, valve protection, and safe riding performance.

How do you use a bike foot pump?

You can use a bike foot pump by placing it on a stable surface, attaching the pump head to the Presta or Schrader valve (with an adapter if needed), then pressing down repeatedly on the foot pedal to compress air into the tire. Use the built-in pressure gauge to monitor PSI/bar, ensuring accurate inflation. Related tools include valve adapters, tire levers, and patch kits for full roadside repair.

How do you use a bike shock pump?

You can use a bike shock pump by connecting its high-pressure, low-volume hose to the suspension fork or rear shock valve, tightening the threaded head to prevent leaks. Pump until the desired PSI/bar is reached, using the integrated gauge for precision, then carefully unscrew the head to avoid air loss. Related terms include air chamber, rebound, sag adjustment, and Schrader valve compatibility.

How do you use a CO2 bike pump?

You can use a CO₂ bike pump by screwing or inserting a CO₂ cartridge into the inflator head, attaching the head to the tire valve (Presta or Schrader), and releasing gas by pressing a trigger or twist valve. The cartridge rapidly fills the tire, so check the tire pressure by feel or gauge to avoid overinflation. Related tools include spare cartridges, inflator heads, and Presta adapters.

How do you use an electric bike pump?

You can use an electric bike pump by selecting the correct valve connector, attaching it to the tire valve, and setting the target PSI/bar on the digital or manual control. Start the pump, and it will automatically inflate the tire and stop when the set pressure is reached. Related tools include USB chargers, Presta/Schrader adapters, and pressure calibration kits, which ensure reliability and accuracy.

How long does it take to pump a bike tire?

A typical bike tire takes 1–3 minutes with a floor pump, 5–10 minutes with a mini pump, and under 30 seconds with a CO₂ inflator, depending on tire size and pump type. Related terms: high volume vs. high pressure, PSI, stroke efficiency, CO₂ cartridge capacity. The time varies because road tires require high pressure but less volume, while MTB tires need high volume but lower PSI.

How much PSI can a bike pump produce?

Most floor pumps produce up to 160 PSI (11 bar), mini pumps around 90–120 PSI (6–8 bar), and shock pumps up to 300 PSI (20 bar) for suspension systems. Related terms: pressure gauge accuracy, pump head seal, Presta/Schrader valve compatibility. The maximum PSI matters because road bikes demand higher pressure, while MTB tires and shocks require lower but more controlled pressure.

How much should you pump a bike tire?

You should pump a bike tire until it reaches the manufacturer-recommended PSI range printed on the tire sidewall, which balances rolling resistance, comfort, and puncture protection. Related terms: tire volume, rider weight, terrain, tubeless setup, pinch flats. This ensures optimal performance without risking blowouts or underinflation.

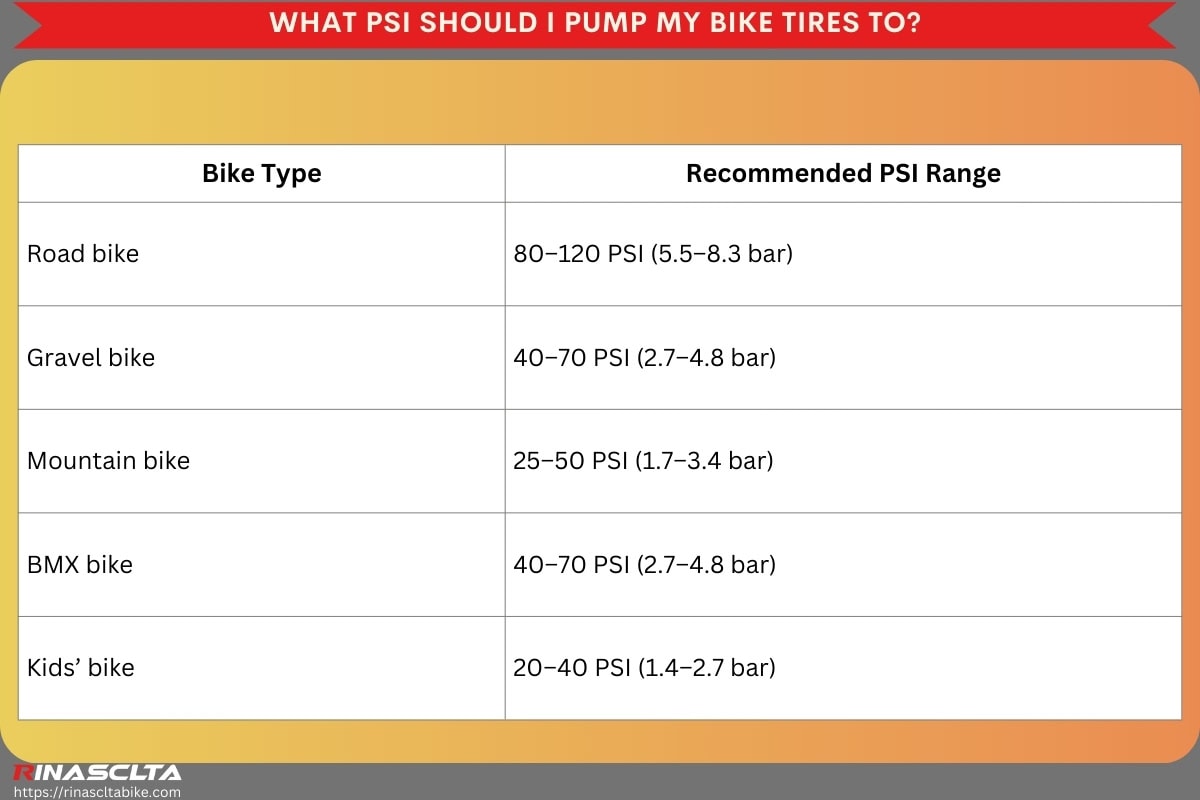

What PSI should I pump my bike tires to?

You should pump your bike tires to the correct PSI (pounds per square inch) based on your bike type, tire width, rider weight, and terrain, because proper inflation affects rolling resistance, grip, comfort, and puncture resistance. Underinflated tires feel sluggish and risk pinch flats, while overinflated tires reduce traction and comfort. The recommended ranges are usually printed on the tire sidewall, but here’s a general guideline as table below.

| Bike Type | Recommended PSI Range |

| Road bike | 80–120 PSI (5.5–8.3 bar) |

| Gravel bike | 40–70 PSI (2.7–4.8 bar) |

| Mountain bike | 25–50 PSI (1.7–3.4 bar) |

| BMX bike | 40–70 PSI (2.7–4.8 bar) |

| Kids’ bike | 20–40 PSI (1.4–2.7 bar) |

How do you pump a bike tyre up?

You can pump a bike tyre up by attaching the pump head to the Presta or Schrader valve, creating an airtight seal, and inflating until the tire reaches the recommended PSI printed on the sidewall.

How do you pump up a tubeless bike tire?

You can pump up a tubeless tire using a high-volume floor pump or tubeless booster chamber, rapidly seating the tire bead onto the rim before inflating to the correct pressure. Related terms: sealant, bead seating, PSI range, air chamber, compressor compatibility.

How do you pump a bike tire without a pump?

You can inflate a bike tire without a pump using CO₂ inflators, air compressors, or improvised pumps like a ball pump with an adapter, but precision is limited and overinflation risk is higher. Related terms: CO₂ cartridges, Presta/Schrader adapter, PSI accuracy.

Can you pump a car tire with a bike pump?

Yes, you can pump a car tire with a bike pump, because both use the same Schrader valve system, allowing air transfer without an adapter. However, it is highly impractical, since car tires require much higher volume than bike tires—often 30–35 PSI across a large chamber—meaning it could take hundreds of strokes and 15–30 minutes with a floor pump, and even longer with a mini pump. Related terms: air volume vs. pressure, stroke efficiency, PSI range, valve compatibility. The value lies only in emergency use, as a bike pump is reliable but not efficient for inflating full-size car tires.

How do you inflate a bike tire with a ball pump?

You can use a ball pump by attaching a Presta-to-Schrader adapter or inserting a needle adaptor into the valve, then pumping, though reaching high PSI (80–120 for road bikes) is difficult. Related terms: low volume, adapter fitting, air pressure limitations.

How do you inflate a bike tire with a car pump?

You can inflate a bike tire with a car pump or compressor if the valve is Schrader or with a Presta adapter, but monitor closely with a separate gauge because car pumps deliver air too quickly and can blow out tubes. Related terms: PSI limits, valve adapter, overinflation risk.

How do you inflate a bike tire with a hand pump?

You can inflate a tire with a hand pump by attaching the pump head, locking it onto the valve, and manually pumping until the tire feels firm or reaches the target PSI on a gauge. Related terms: portable, roadside repair, stroke efficiency, Presta/Schrader compatibility.

How do you pump bike shocks?

You can pump bike shocks with a specialized high-pressure shock pump, threading it onto the Schrader valve on the suspension fork or shock, and inflating to the recommended 100–300 PSI for your sag and rebound setup. Related terms: suspension tuning, rebound, sag %, PSI/bar, threaded head seal.

How do you pump a road bike?

You can pump a road bike by using a high-pressure floor pump or mini pump, attaching to the Presta valve, and inflating to 80–120 PSI (5.5–8.3 bar) depending on tire width and rider weight. Related terms: PSI accuracy, gauge, rolling resistance, Presta lock nut.

How do you pump a mountain bike?

You can pump a mountain bike by using a high-volume pump that quickly fills wide tires, usually to 25–50 PSI (1.7–3.4 bar), prioritizing traction and comfort. Related terms: tubeless compatibility, volume efficiency, and low-pressure gauge.

How do you pump bike tires at a petrol station?

You can pump bike tires at a petrol station by using the air hose with a Schrader head or with a Presta adapter, inflating in short bursts while checking PSI to avoid overinflation. Related terms: public compressor, adapter use, fast airflow, gauge mismatch.

How do you read a bike pump gauge?

You can read a bike pump gauge by looking at the dial or digital display marked in PSI and bar, stopping when the needle or number matches your tire’s recommended pressure. Related terms: dual-scale gauge, accuracy tolerance, tire sidewall rating.

How do you read PSI on a bike pump?

You can read PSI by checking the outer or inner scale on the pump’s gauge, where PSI is commonly displayed on the outer ring (0–160 PSI) and bar on the inner (0–11 bar), ensuring you stop at the tire’s correct pressure range. Related terms: PSI vs. bar conversion, 1 bar ≈ 14.5 PSI, gauge calibration.

How often do you need to pump your bike tires?

You should pump your bike tires at least once a week for road bikes, every 1–2 weeks for gravel or hybrid bikes, and every 2–3 weeks for mountain bikes, because tire pressure naturally drops over time due to air permeability. Road bikes running at 80–120 PSI (5.5–8.3 bar) lose air faster because of the high pressure and narrow tires, while mountain bikes at 25–50 PSI (1.7–3.4 bar) and gravel bikes at 40–70 PSI (2.7–4.8 bar) hold pressure longer thanks to their larger volume. Related terms include PSI accuracy, rolling resistance, puncture risk, and valve type (Presta or Schrader). Regular pumping ensures optimal performance, safety, comfort, and protection against pinch flats.

How do you attach a bike pump?

You can attach a bike pump by first identifying the valve type (Presta, Schrader, or Dunlop), then fitting the pump head or adapter onto the valve and locking it in place with a lever or threaded head to create an airtight seal. Related terms: valve compatibility, PSI/bar, pump head design, adapter kit.

How do you lubricate a bike pump?

You can lubricate a bike pump by applying a thin layer of silicone-based grease or Teflon lubricant to the piston, O-ring, and seals, ensuring smooth operation and airtight compression.

How do you fix a bike pump?

You can fix a bike pump by diagnosing common issues such as leaky hoses, broken seals, faulty gauges, or stuck pistons, then replacing or repairing the faulty part with a seal kit, replacement hose, or gauge unit. Related terms: O-ring replacement, hose clamp, valve head rebuild kit.

How do you repair a bike pump?

You can repair a bike pump by disassembling it, cleaning the cylinder and seals, replacing any worn gaskets or cracked hoses, reassembling, and testing the pressure gauge for accuracy.

Where can I pump my bike tires for free?

You can pump your bike tires for free at places like public bike repair stations, bike shops, community centers, universities, and some parks or trailheads, which often provide floor pumps or air stations. Many gas stations also allow free use of their air compressors, especially if your bike has Schrader valves or you carry a Presta-to-Schrader adapter. Related terms: public air pump, community repair stand, PSI gauge, valve compatibility, urban cycling infrastructure. These options add value by giving cyclists convenient access to proper tire pressure without needing to carry a full pump.

Why won’t my bike pump air?

Your bike pump won’t air because the pump head isn’t sealed properly on the valve, the O-ring or gasket is worn, or the check valve inside the pump is faulty, preventing airflow. Related terms: valve compatibility, seal leak, PSI transfer, adapter use.

Why won’t my bike pump push down?

Your bike pump won’t push down because the piston or cylinder is jammed, the internal seals are dry or damaged, or the pump is already at high PSI and needs more force. Related terms: piston binding, O-ring lubrication, stroke resistance.

Why won’t my bike pump’s valve stay on?

Your bike pump’s valve won’t stay on because the pump head lever isn’t locking correctly, the seal is worn or cracked, or you’re using the wrong head for Presta vs. Schrader valves. Related terms: valve head design, adapter fitting, airtight seal.

Why is my bike pump deflating my tires?

Your bike pump is deflating your tires because the check valve inside the pump head is reversed or leaking, or the valve core on the tire is loose, causing air to escape when disconnecting. Related terms: backflow prevention, valve core tightening, seal integrity.

Why is my bike tire not pumping up?

Your bike tire is not pumping up because the pump isn’t aligned with the valve, the valve core is stuck or damaged, or the pump isn’t delivering enough PSI/volume to inflate the tube. Related terms: airflow obstruction, valve maintenance, pressure mismatch.

Why is my bike pump pushing back?

Your bike pump is pushing back because air is trapped or compressed in the hose without entering the tire, often due to a blocked valve, clogged pump head, or overpressure inside the tire. Related terms: back pressure, check valve failure, stroke resistance.

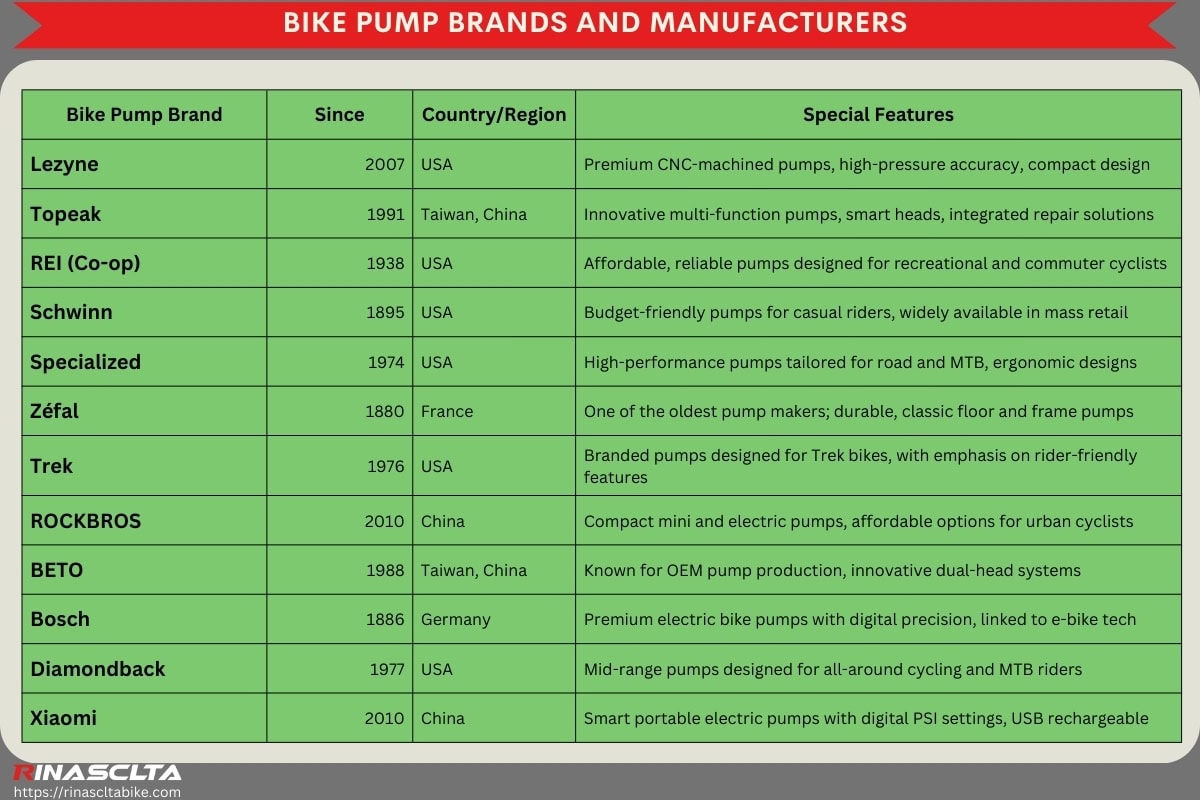

Bike pump brands and manufacturers

Bike pump brands and manufacturers make up an important segment of the cycling industry, producing tools that keep bicycles safe, efficient, and performance-ready. From century-old European brands like Zéfal, which pioneered pump technology, to modern innovators like Lezyne, Topeak, and Xiaomi, these companies cater to diverse rider needs with products ranging from durable workshop floor pumps to compact mini and electric pumps. The industry balances tradition and innovation—some brands focus on high-pressure precision for road cyclists, others on high-volume pumps for mountain bikes, and more recently, portable electronic pumps have emerged for convenience. Understanding the history, origin, and features of each brand helps cyclists choose pumps that deliver the right mix of reliability, accuracy, and portability.

| Bike Pump Brand | Since | Country/Region | Special Features |

| Lezyne | 2007 | USA | Premium CNC-machined pumps, high-pressure accuracy, compact design |

| Topeak | 1991 | Taiwan, China | Innovative multi-function pumps, smart heads, integrated repair solutions |

| REI (Co-op) | 1938 | USA | Affordable, reliable pumps designed for recreational and commuter cyclists |

| Schwinn | 1895 | USA | Budget-friendly pumps for casual riders, widely available in mass retail |

| Specialized | 1974 | USA | High-performance pumps tailored for road and MTB, ergonomic designs |

| Zéfal | 1880 | France | One of the oldest pump makers; durable, classic floor and frame pumps |

| Trek | 1976 | USA | Branded pumps designed for Trek bikes, with emphasis on rider-friendly features |

| ROCKBROS | 2010 | China | Compact mini and electric pumps, affordable options for urban cyclists |

| BETO | 1988 | Taiwan, China | Known for OEM pump production, innovative dual-head systems |

| Bosch | 1886 | Germany | Premium electric bike pumps with digital precision, linked to e-bike tech |

| Diamondback | 1977 | USA | Mid-range pumps designed for all-around cycling and MTB riders |

| Xiaomi | 2010 | China | Smart portable electric pumps with digital PSI settings, USB rechargeable |