Bike brake pads are small but essential components of a bicycle’s braking system, responsible for generating friction against either the rim or rotor to slow down or stop the bike. Introduced in early rim-brake systems in the late 19th century and evolving significantly with the rise of disc brakes in the 1990s—driven by brands like Shimano (Japan), Magura (Germany), and SRAM (USA)—brake pads have diversified into materials like resin, sintered metal, ceramic, and semi-metallic compounds. Bike brake pads play a critical role in braking performance, pad life, rotor wear, and rider safety, making it vital to choose the right type based on bike discipline, terrain, and weather conditions. This article explains bike brake pads, the types available, and how to choose, replace, and maintain them for long-term performance and value.

This article covers the definition, types, selection process, and maintenance tips for bike brake pads to help you optimize braking performance, safety, and durability across different riding conditions.

Table of Contents

What are bike brake pads?

Bike brake pads are friction components that press against the rim or rotor to slow down or stop a bicycle, converting kinetic energy into heat through direct contact. First developed in the late 1800s alongside early coaster and rim brake systems in Europe and the U.S., they have evolved from basic leather and rubber pads into modern high-performance materials like resin, metallic, ceramic, and semi-metallic compounds—engineered by companies such as Shimano, Magura, and SRAM to suit different terrains, weather conditions, and braking systems (rim or disc).

How do bike brake pads work?

Bike brake pads work by pressing against a braking surface—either the rim or a rotor—using mechanical or hydraulic force from the brake caliper, creating friction that slows the wheel’s rotation and eventually stops the bike. The pads convert kinetic energy into heat, and their effectiveness depends on material type, pad-to-surface contact, and how efficiently the braking system transfers lever input to stopping force.

How do bike rim brake pads work?

Bike rim brake pads are pressed directly against the wheel’s rim by the brake arms when the lever is pulled, using cable tension to generate the required force. The friction between the rubber or compound pad and the metal rim slows the bike, with performance influenced by pad alignment, rim condition, and weather—especially in wet or dirty environments where efficiency drops.

How do bike disc brake pads work?

Bike disc brake pads are housed in a caliper that squeezes them onto a metal rotor attached to the hub, using either a hydraulic system or mechanical cable to apply braking force. This system isolates braking from the rim, offering better heat dissipation, stronger stopping power, and consistent performance in all weather—making it highly efficient for mountain, gravel, and modern road bikes.

Do all bikes have brake pads?

No, because some bikes, such as fixed-gear track bikes or coaster brake bikes, rely on hub-based braking or pedal resistance instead of conventional caliper or disc brakes that use pads. However, the majority of bikes—road, mountain, gravel, and hybrids—do use brake pads as friction elements for stopping.

Are all bike brake pads the same?

No, because brake pads vary in shape, size, compound, and intended use, depending on the type of braking system (rim or disc), brand compatibility (e.g., Shimano, SRAM), and riding conditions. Using the wrong pad can cause poor performance, noise, or damage to the rotor or rim.

Are bike disc brake pads universal?

No, because bike disc brake pads are designed to fit specific caliper models, with different shapes, backplate styles, and retention methods that vary by brand and brake series. Compatibility must match the brake caliper to ensure proper fit and safe braking.

Are mountain bike brake pads universal?

No, because even within mountain biking, different brake brands and models (e.g., Shimano 2-piston vs. 4-piston, SRAM Code vs. Level) use different pad shapes and sizes. Pad compatibility depends on the exact caliper design and brake system, not just the bike category.

Do disc brakes on bikes have pads?

Yes, because disc brake systems require brake pads housed in the caliper to press against the rotor, which is how the braking force is applied. These pads come in various compounds (resin, sintered, etc.) and are crucial for generating friction to stop the bike.

Are brakes and brake pads the same thing?

No, because brakes refer to the complete braking system—including levers, calipers, cables/hoses, and pads—while brake pads are just one component that directly contacts the braking surface (rim or rotor) to create friction and stop the bike.

What are the materials of bike brake pads?

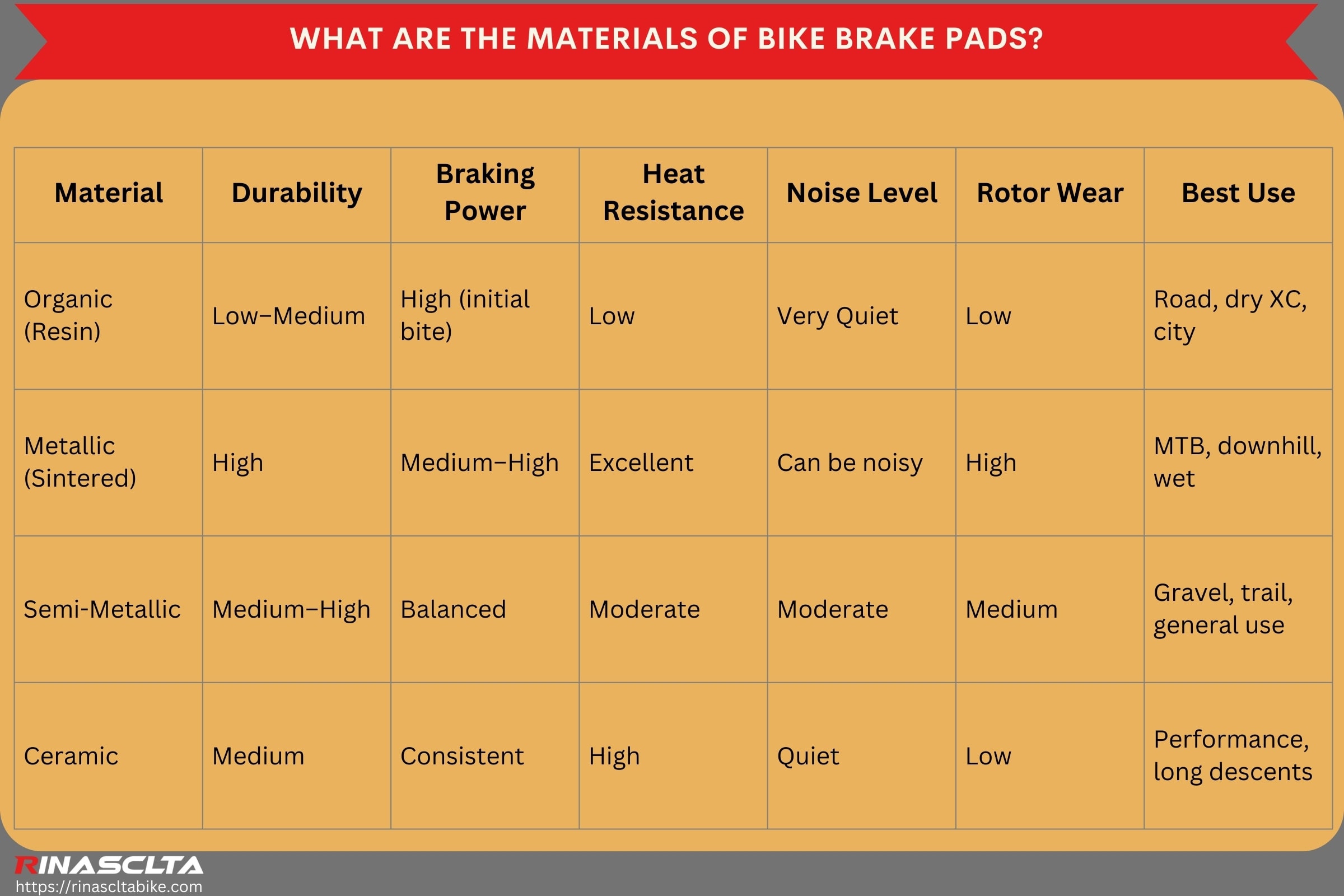

The materials of bike brake pads include organic (resin), metallic (sintered), semi-metallic, and ceramic, each selected for their balance of durability, braking efficiency, heat resistance, noise level, and rotor wear. These materials are used to suit different riding conditions—such as dry road, wet trails, or aggressive downhill—and affect how the pad feels and performs under braking.

- Organic (Resin): Organic pads are made from non-metallic compounds like rubber, Kevlar, and resin, offering smooth, quiet braking with low rotor wear but a shorter lifespan.

- Metallic (Sintered): Metallic pads use hardened metal particles fused under high heat, delivering excellent durability and heat resistance, ideal for wet, muddy, or high-speed conditions.

- Semi-Metallic: Semi-metallic pads combine metal shavings with resin binders to balance the quietness of organic pads and the strength of metallic ones, suitable for all-around use.

- Ceramic: Ceramic pads use ceramic fibers and non-ferrous materials for high heat tolerance, quiet operation, and minimal fade, often used in high-performance or long-descent settings.

| Material | Durability | Braking Power | Heat Resistance | Noise Level | Rotor Wear | Best Use |

| Organic (Resin) | Low–Medium | High (initial bite) | Low | Very Quiet | Low | Road, dry XC, city |

| Metallic (Sintered) | High | Medium–High | Excellent | Can be noisy | High | MTB, downhill, wet |

| Semi-Metallic | Medium–High | Balanced | Moderate | Moderate | Medium | Gravel, trail, general use |

| Ceramic | Medium | Consistent | High | Quiet | Low | Performance, long descents |

Resin vs metal bike disc brake pads

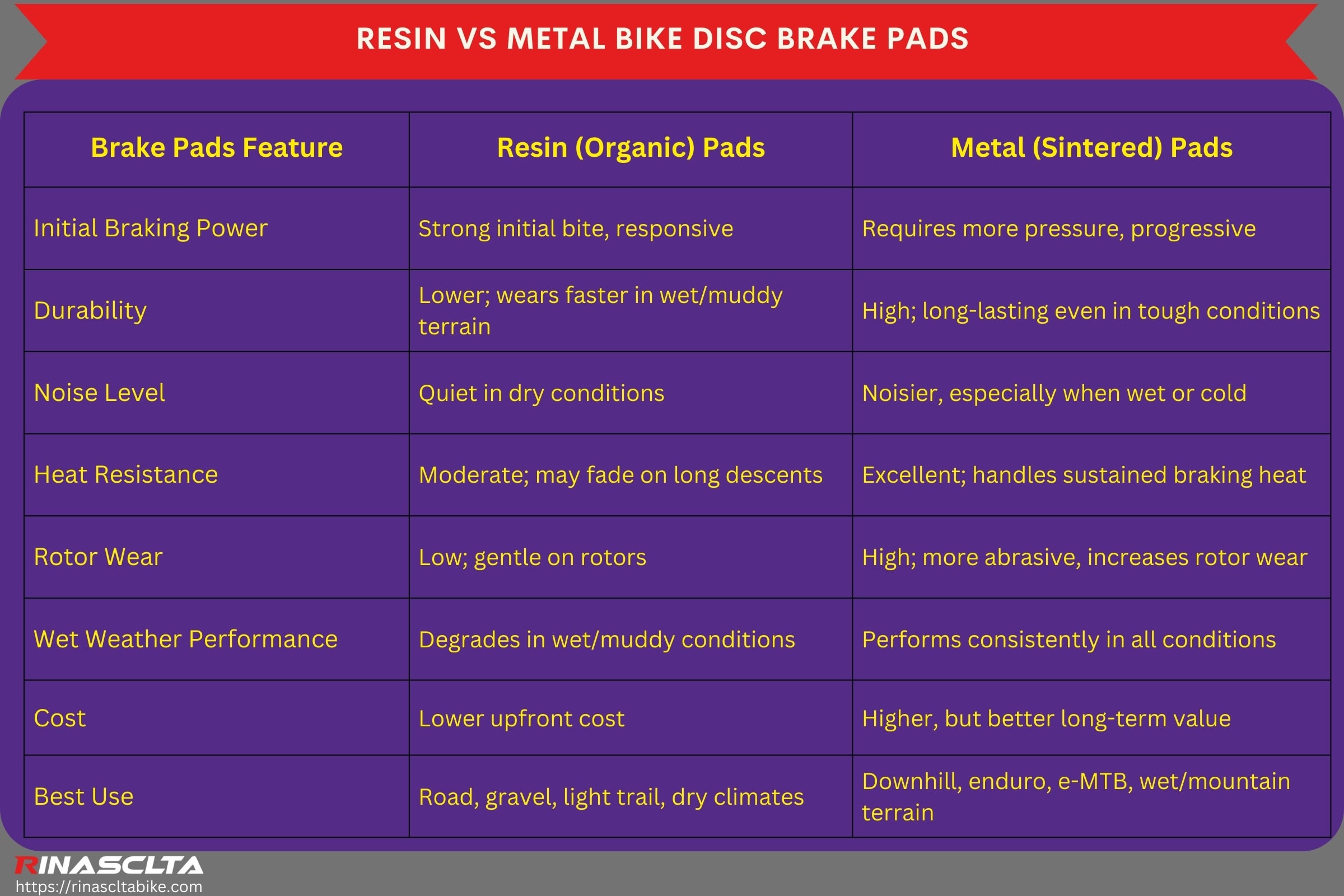

Resin vs. metal bike disc brake pads is a key comparison for cyclists because both offer different braking characteristics suited to specific riding styles, terrain, and weather. Resin (organic) pads are known for smooth, quiet braking and rotor friendliness, while metal (sintered) pads are valued for their durability and wet-weather performance. Choosing between them depends on factors like noise tolerance, heat resistance, longevity, and pad feel.

| Brake Pads Feature | Resin (Organic) Pads | Metal (Sintered) Pads |

| Initial Braking Power | Strong initial bite, responsive | Requires more pressure, progressive |

| Durability | Lower; wears faster in wet/muddy terrain | High; long-lasting even in tough conditions |

| Noise Level | Quiet in dry conditions | Noisier, especially when wet or cold |

| Heat Resistance | Moderate; may fade on long descents | Excellent; handles sustained braking heat |

| Rotor Wear | Low; gentle on rotors | High; more abrasive, increases rotor wear |

| Wet Weather Performance | Degrades in wet/muddy conditions | Performs consistently in all conditions |

| Cost | Lower upfront cost | Higher, but better long-term value |

| Best Use | Road, gravel, light trail, dry climates | Downhill, enduro, e-MTB, wet/mountain terrain |

Ceramic vs semi-metallic brake pads

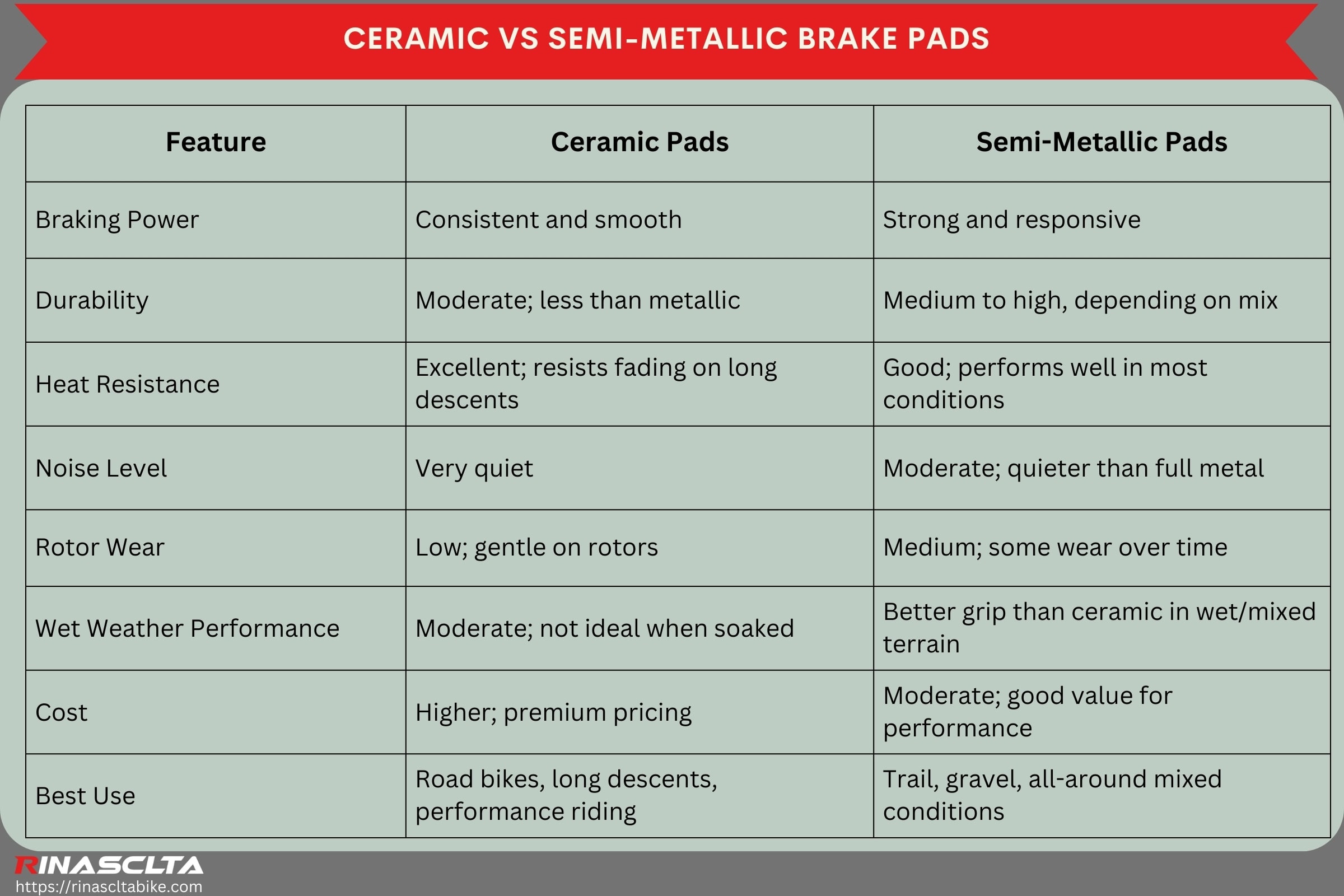

Ceramic vs. semi-metallic brake pads is a useful comparison because both offer a balance of braking performance, durability, and noise control, but are suited to different riding conditions and bike types. Ceramic pads are known for quiet operation, minimal rotor wear, and heat resistance, making them ideal for long descents or performance road use. Semi-metallic pads, on the other hand, combine metal and resin to provide strong stopping power and versatility across terrain, making them a common choice for trail and gravel riders.

| Feature | Ceramic Pads | Semi-Metallic Pads |

| Braking Power | Consistent and smooth | Strong and responsive |

| Durability | Moderate; less than metallic | Medium to high, depending on mix |

| Heat Resistance | Excellent; resists fading on long descents | Good; performs well in most conditions |

| Noise Level | Very quiet | Moderate; quieter than full metal |

| Rotor Wear | Low; gentle on rotors | Medium; some wear over time |

| Wet Weather Performance | Moderate; not ideal when soaked | Better grip than ceramic in wet/mixed terrain |

| Cost | Higher; premium pricing | Moderate; good value for performance |

| Best Use | Road bikes, long descents, performance riding | Trail, gravel, all-around mixed conditions |

Which is better, ceramic or semi-metallic brake pads?

Ceramic brake pads are better than semi-metallic pads for road biking, long descents, and quiet, smooth braking because they offer excellent heat resistance, low rotor wear, and very quiet operation. But semi-metallic brake pads are better than ceramic for trail, gravel, and all-weather riding because they provide stronger initial bite, better grip in wet or muddy conditions, and more versatile performance across mixed terrain.

Ceramic brake pads vs metallic brake pads

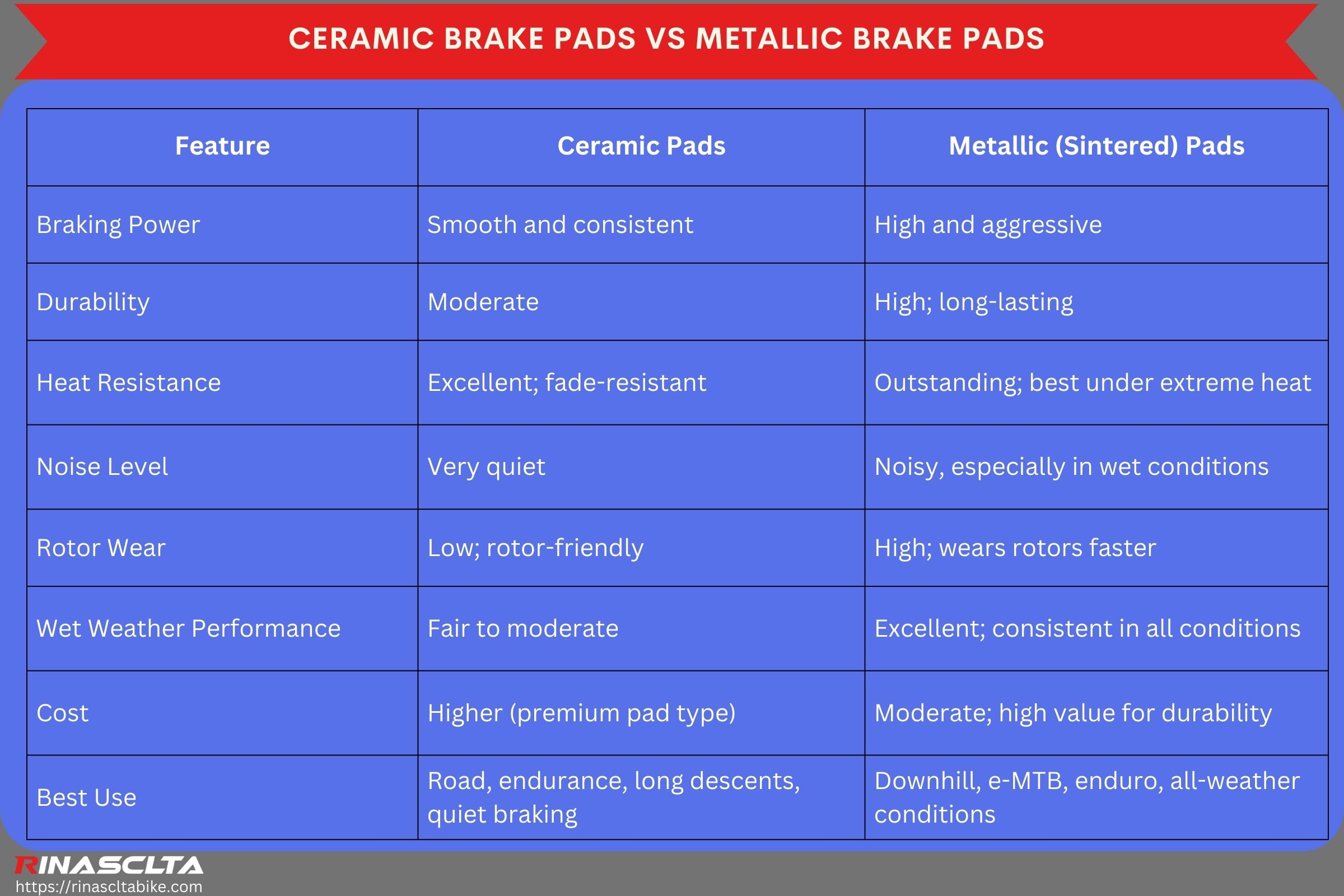

Ceramic brake pads vs. metallic brake pads is a key comparison because both are high-performance options but cater to very different riding styles and conditions. Ceramic pads prioritize smooth, quiet braking and rotor longevity, making them ideal for road, endurance, and downhill control on long descents. Metallic (sintered) pads, by contrast, excel in durability, wet-weather grip, and extreme heat tolerance, making them the go-to choice for aggressive mountain biking, e-bikes, and all-weather riding. Riders compare them to balance performance, noise, wear, and terrain suitability.

| Feature | Ceramic Pads | Metallic (Sintered) Pads |

| Braking Power | Smooth and consistent | High and aggressive |

| Durability | Moderate | High; long-lasting |

| Heat Resistance | Excellent; fade-resistant | Outstanding; best under extreme heat |

| Noise Level | Very quiet | Noisy, especially in wet conditions |

| Rotor Wear | Low; rotor-friendly | High; wears rotors faster |

| Wet Weather Performance | Fair to moderate | Excellent; consistent in all conditions |

| Cost | Higher (premium pad type) | Moderate; high value for durability |

| Best Use | Road, endurance, long descents, quiet braking | Downhill, e-MTB, enduro, all-weather conditions |

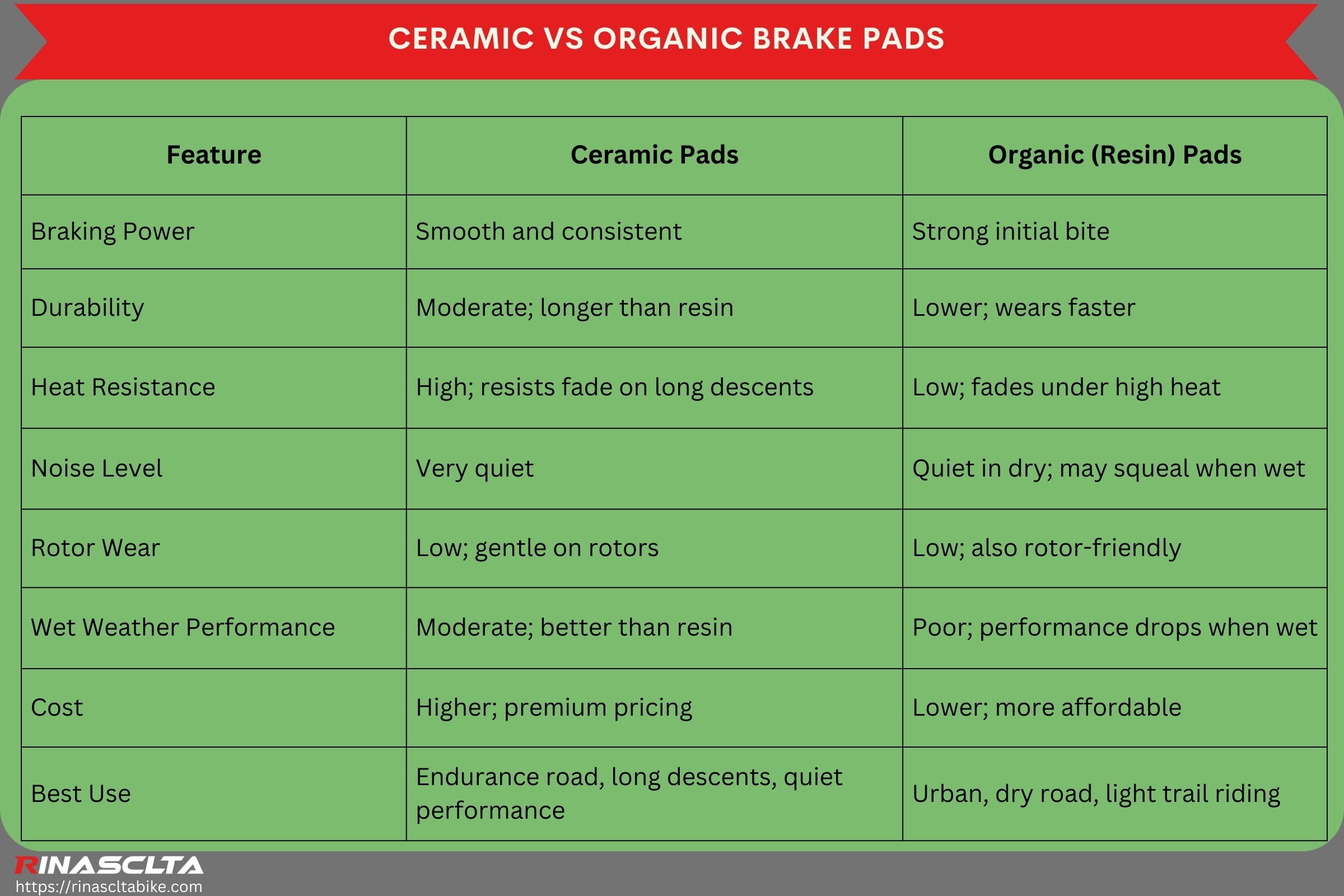

Ceramic vs organic brake pads

Ceramic vs. organic (resin) brake pads is a useful comparison because both offer quiet, rotor-friendly braking but differ in performance, heat resistance, and durability. Riders often compare these pads to determine which offers better value and function for road, urban, or light trail use, where quietness and modulation are important. While organic pads are affordable and offer a strong initial bite, ceramic pads perform more consistently under heat and last longer—making the right choice dependent on your riding style and terrain.

| Feature | Ceramic Pads | Organic (Resin) Pads |

| Braking Power | Smooth and consistent | Strong initial bite |

| Durability | Moderate; longer than resin | Lower; wears faster |

| Heat Resistance | High; resists fade on long descents | Low; fades under high heat |

| Noise Level | Very quiet | Quiet in dry; may squeal when wet |

| Rotor Wear | Low; gentle on rotors | Low; also rotor-friendly |

| Wet Weather Performance | Moderate; better than resin | Poor; performance drops when wet |

| Cost | Higher; premium pricing | Lower; more affordable |

| Best Use | Endurance road, long descents, quiet performance | Urban, dry road, light trail riding |

What is the bike brake pad thickness?

The bike brake pad thickness typically starts at 3 to 4 mm of usable pad material (excluding the backing plate) for both disc and rim brake pads, depending on the type and manufacturer. For disc brake pads, most brands recommend replacing the pads when the material wears down to 1 mm or less, as performance drops and rotor damage becomes more likely; rim brake pads usually begin around 5 mm in total thickness and should be replaced when the wear line or groove disappears. Thickness affects braking power, heat tolerance, and safety—so regular inspection is key to maintaining optimal performance.

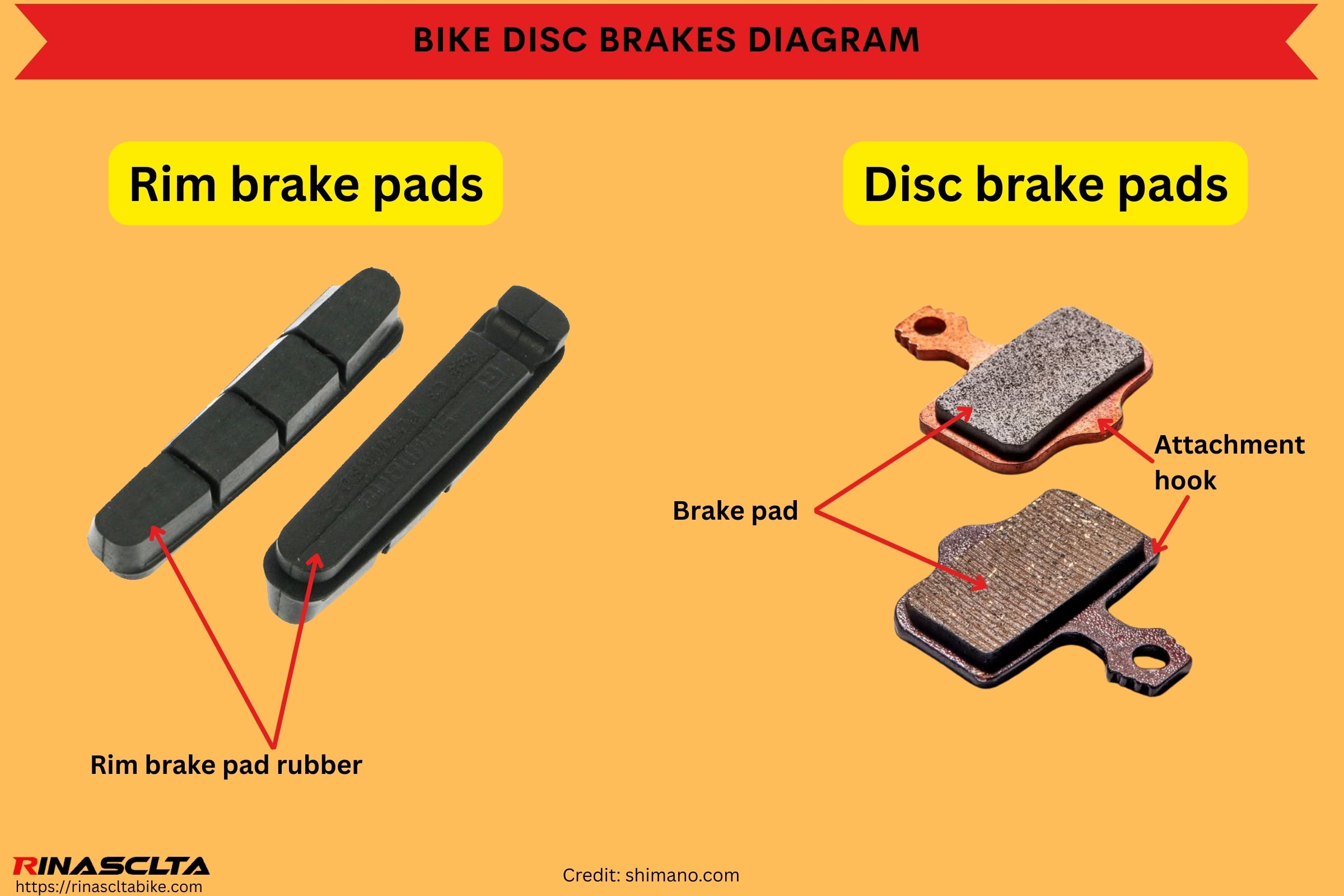

Bike brake pads diagram

A bike brake pads diagram visually illustrates the key components—such as the friction material, backing plate, spring clip, and pad shape—which are essential for identifying pad types, ensuring correct installation, and understanding how braking force is applied and maintained in both disc and rim brake systems.

Types of bike brake pads

The types of bike brake pads are primarily sorted by brake type (rim or disc) and bike type (road, mountain, e-bike, exercise bike, fat bike), as each category requires specific shapes, materials, and performance characteristics suited to the braking system and riding demands. This classification helps riders select the correct pad for optimal braking efficiency, safety, and compatibility with their bike’s calipers, rotors, or rims.

Bike brake pads sorted by brake types

Bike brake pads sorted by brake types include rim brake pads and disc brake pads, classified based on the braking surface they contact—either the wheel rim or a separate disc rotor. This sorting is essential because each pad type is engineered to match the mechanical structure, heat tolerance, and friction requirements of its respective braking system.

- Bike Rim Brake Pads: Bike rim brake pads press directly against the wheel’s metal sidewalls and are typically made from rubber or compound blends to balance smooth braking and minimal rim wear.

- Bike Disc Brake Pads: Bike disc brake pads clamp onto a rotor attached to the wheel hub and come in materials like resin, metallic, ceramic, or semi-metallic to handle high temperatures and varying trail or road conditions.

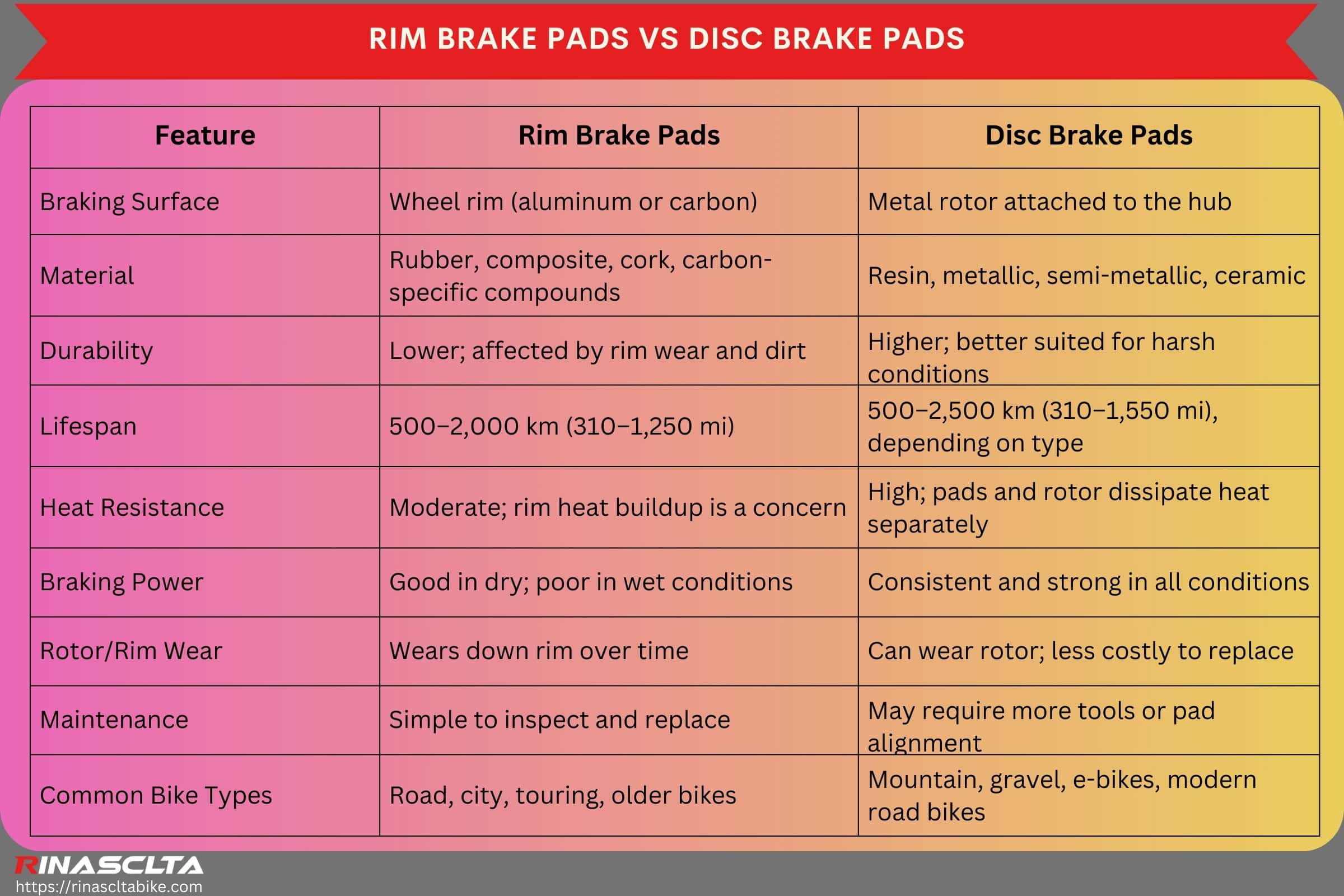

Rim brake pads vs disc brake pads

Rim brake pads vs. disc brake pads is a relevant comparison because both serve the same function—slowing the bike—but work in entirely different braking systems with unique materials, shapes, and performance requirements. Understanding their differences helps riders choose the right pads for their bike type, riding environment, and maintenance expectations, as each excels in different aspects like heat management, rotor/rim wear, and braking consistency.

| Feature | Rim Brake Pads | Disc Brake Pads |

| Braking Surface | Wheel rim (aluminum or carbon) | Metal rotor attached to the hub |

| Material | Rubber, composite, cork, carbon-specific compounds | Resin, metallic, semi-metallic, ceramic |

| Durability | Lower; affected by rim wear and dirt | Higher; better suited for harsh conditions |

| Lifespan | 500–2,000 km (310–1,250 mi) | 500–2,500 km (310–1,550 mi), depending on type |

| Heat Resistance | Moderate; rim heat buildup is a concern | High; pads and rotor dissipate heat separately |

| Braking Power | Good in dry; poor in wet conditions | Consistent and strong in all conditions |

| Rotor/Rim Wear | Wears down rim over time | Can wear rotor; less costly to replace |

| Maintenance | Simple to inspect and replace | May require more tools or pad alignment |

| Common Bike Types | Road, city, touring, older bikes | Mountain, gravel, e-bikes, modern road bikes |

Bike brake pads sorted by bike type

Bike brake pads sorted by bike type include road, mountain, e-bike, exercise bike, and fat bike pads, categorized this way because each type of bike demands specific braking characteristics based on terrain, speed, rider weight, and system compatibility. This sorting ensures riders choose pads with the right material, shape, and performance to match their bike’s braking system and use case.

- Bike Road Brake Pads: Bike road brake pads are designed for lightweight, high-speed bikes and prioritize smooth modulation, low weight, and compatibility with both aluminum and carbon rims or small-diameter disc rotors.

- Bike Mountain Brake Pads: Bike mountain brake pads are built for power and durability on steep and technical terrain, often using metallic or semi-metallic compounds to handle heat and mud.

- Bike E-Bike Brake Pads: Bike e-bike brake pads are made with reinforced compounds to withstand higher speeds and heavier loads, offering enhanced stopping power and longer wear life.

- Bike Exercise Bike Brake Pads: Bike exercise bike pads are typically designed for indoor use with flywheel systems, using smooth composite or felt materials to provide steady resistance rather than sudden stops.

- Bike Fat Bike Brake Pads: Bike fat bike brake pads are optimized for braking in snow, sand, and off-road conditions, often favoring sintered compounds and wider pad profiles for consistent grip and control.

How do you choose bike brake pads?

You can choose bike brake pads by considering key factors such as brake type, pad material (compound), bike type, riding conditions, weather, budget, noise level, shape, compatibility, reliability, and performance needs—because each influences braking power, durability, rotor wear, fit, and overall safety across different systems and terrains.

- Brake Type: Choose pads designed for rim or disc systems to ensure proper fit and function within the brake caliper.

- Pad Material (Compound): Pick from resin, metallic, semi-metallic, or ceramic based on your priorities for heat resistance, noise, and pad life.

- Bike Type: Match the pad to your bike style—road, mountain, e-bike, etc.—to meet the expected braking force and weight demands.

- Riding Conditions: Select pads suited for your terrain, such as trail, city, or downhill, which affects brake heat, wear rate, and control.

- Weather: Choose materials like metallic for wet and muddy environments or resin for dry conditions and smooth engagement.

- Budget: Consider resin pads for affordability or invest in ceramic or sintered options for better performance and longevity.

- Noise Level: Opt for quieter compounds like resin or ceramic if you ride in quiet environments or group settings.

- Shape: Use the correct pad shape that matches your specific caliper design to ensure proper alignment, contact, and braking efficiency.

- Compatibility: Verify that the pads match your brake brand and caliper model (e.g., Shimano M6100, SRAM Level, Magura MT) for correct fit and safety.

- Reliability: Choose pads from trusted brands or tested compounds to ensure consistent performance under pressure, in descents, or long rides.

How do you choose bike rim brake pads?

You can choose bike rim brake pads by matching them to your rim material—aluminum or carbon—as this determines the compound needed for safe and efficient braking. For aluminum rims, standard rubber or all-weather pads offer smooth, affordable performance, while carbon rims require carbon-specific pads to prevent heat damage and preserve braking power. You should also consider brake type compatibility (e.g., caliper, cantilever, or V-brake), riding conditions, and pad shape to ensure proper fit and consistent modulation.

How do you choose bike disc brake pads?

You can choose bike disc brake pads based on your caliper model, riding style, and pad compound—resin (organic), metallic (sintered), semi-metallic, or ceramic. For mountain biking or wet weather, metallic or semi-metallic pads provide better durability and performance, while resin or ceramic pads are preferred for road cycling or urban riding due to quieter operation and smoother engagement. Always confirm brand compatibility (e.g., Shimano, SRAM, Magura), rotor compatibility, and the pad’s shape to ensure safe, optimal braking.

How do you install bike brake pads?

You can install bike brake pads by removing the wheel, opening the brake caliper, taking out the old pads, inspecting the rotor or rim, inserting the new pads, aligning them correctly, and testing the brakes—each step ensures proper contact, safe braking performance, and pad longevity.

- Remove the Wheel: You can remove the wheel to access the brake area safely and avoid damaging the rotor or rim during pad installation.

- Open the Brake Caliper: You can open the caliper by loosening the retaining pin, bolt, or spring clip, allowing access to the old pads.

- Take Out the Old Pads: You can remove the worn pads using pliers or an Allen key, making note of their orientation for correct replacement.

- Inspect the Rotor or Rim: You can check the rotor (disc) or rim (rim brake) for wear, dirt, or warping, ensuring your new pads make clean, even contact.

- Insert the New Pads: You can slide the new pads into the caliper or brake shoe until they click or seat firmly in place.

- Align the Pads: You can adjust the pad position so they contact the rotor or rim evenly without rubbing or misalignment.

- Test the Brakes: You can squeeze the brake lever and spin the wheel to check for proper pad engagement and clearance.

How do you replace bike brake pads?

You can replace bike brake pads by removing the wheel, taking out the old pads from the caliper or brake arm, and installing new ones in the same orientation. You should also clean the rotor or rim and verify proper pad alignment to ensure optimal braking performance and pad longevity.

How do you replace brake pads on a mountain bike?

You can replace mountain bike brake pads—typically disc pads—by removing the wheel, pulling out the pad retention pin or bolt, sliding the old pads out of the caliper, and pushing the pistons back before inserting new pads. Use a piston reset tool or a plastic tire lever, and finish by aligning the caliper and testing the brake lever feel.

How do you change hydraulic brake pads bike?

You can change hydraulic brake pads by removing the wheel, opening the pad retaining bolt or clip, and using pliers to slide the pads out of the hydraulic caliper. After resetting the pistons, install the new pads, secure them, and pump the brake lever to seat the pads evenly against the rotor.

How do you replace bike rim brake pads?

You can replace rim brake pads by loosening the small retention bolt or sliding pad holder screw with a 5 mm Allen key, removing the old pad, and sliding the new one into the same holder. Make sure to align the pad so it contacts the braking surface squarely without touching the tire or dipping below the rim.

How do you set bike brakes after changing pads?

You can set bike brakes after pad replacement by squeezing the brake lever several times to seat the pads, then centering the caliper or brake arms over the rotor or rim. Ensure proper clearance and no rubbing by adjusting tension screws or caliper bolts for balanced braking.

How do you adjust bike brake pads?

You can adjust bike brake pads by loosening their mounting bolt, repositioning the pad so it sits flat against the braking surface, and re-tightening with the correct angle and spacing. Check that both sides engage evenly and don’t rub when the lever is released.

How do you adjust disc brake pads bike?

You can adjust disc brake pads by loosening the caliper bolts, pulling the brake lever to center the caliper over the rotor, then tightening the bolts while holding the lever. For mechanical brakes, you can also fine-tune pad clearance using the barrel adjuster or inner pad dial.

How do you adjust the rim brake pads bike?

You can adjust rim brake pads by loosening the pad fixing bolt, aligning the pad with the rim braking track, and ensuring it’s not touching the tire or dipping below the rim edge. Use a feeler gauge or credit card to ensure a slight toe-in to reduce brake squeal.

Can you mix and match brake pads and calipers bike?

No, you can’t mix and match brake pads and calipers indiscriminately because brake pads are designed to fit specific caliper models, shapes, and pad retention systems (e.g., Shimano, SRAM, Magura). Using an incompatible pad can result in poor fit, unsafe braking, noise, or damage to the brake system.

How do you stop bike brake pads from squeaking?

You can stop bike brake pads from squeaking by cleaning the pads and braking surface with isopropyl alcohol or a bike-specific disc brake cleaner, and lightly sanding the pad surface with fine-grit sandpaper if glazed. For rim brakes, you can also adjust the toe-in—slightly angling the front of the pad toward the rim—to reduce vibration and noise.

How do you adjust the bike brake pad alignment?

You can adjust bike brake pad alignment by loosening the pad bolt with a 5 mm Allen key, then repositioning the pad so it sits flat and centered against the rim braking surface (for rim brakes) or evenly contacts the rotor (for disc brakes). Proper alignment ensures full surface contact, prevents noise or uneven wear, and maximizes braking efficiency and pad lifespan.

Why are bike brake pads not making full contact?

Bike brake pads are not making full contact because they may be misaligned, worn unevenly, or mounted at the wrong angle, which causes only part of the pad to touch the braking surface. Other causes include improper caliper centering, rotor warping, or rim deformities, all of which reduce braking power and increase wear.

How do you stop brake pads from rubbing on a bike?

You can stop brake pads from rubbing by centering the caliper (for disc brakes) or adjusting the brake arm tension and pad alignment (for rim brakes) so that the pads retract evenly and clear the rotor or rim. For hydraulic disc brakes, make sure the pistons are reset fully using a piston press tool or a plastic tire lever.

Why does the brake pad move when applying brakes on a mountain bike?

The brake pad moves when applying brakes on a mountain bike because it is either not properly seated, the retaining pin or bolt is loose, or the pad spring is worn or misaligned, allowing it to shift under braking force. This movement can cause noise, uneven wear, or poor braking performance and should be corrected by inspecting the caliper assembly and ensuring all pad hardware is securely installed and correctly aligned.

How do you clean bike brake pads?

You can clean bike brake pads by removing them from the caliper or holder and scrubbing the surface gently with fine sandpaper (around 120–200 grit) to remove glazing, then wiping them with isopropyl alcohol to eliminate oil, dirt, and debris. Avoid touching the braking surface with your fingers afterward to prevent re-contamination.

Is it okay to clean bike brake pads in acetone?

No, you can’t safely clean bike brake pads with acetone because it is too aggressive and can degrade pad material, adhesives, and rubber parts—especially on resin-based pads. Stick to isopropyl alcohol (90%+) or a brake-specific cleaner, which effectively removes oil and grime without damaging the compound.

When do you replace bike brake pads?

You can replace bike brake pads when the pad material is worn down to 1 mm or less, or when you notice reduced braking power, squealing, or uneven pad wear. Pads should also be replaced if contaminated with oil or if they feel spongy or inconsistent during braking.

How long do bike brake pads last?

Bike brake pads normally last between 500–2,000 km (310–1,250 miles), depending on the compound, riding terrain, weather, and braking habits. Harder compounds like sintered metal last longer, while softer organic pads wear quicker but offer quieter, smoother braking.

How long do bike disc brake pads last?

Bike disc brake pads normally last around 500–2,500 km (310–1,550 miles), with resin pads wearing faster than metallic or semi-metallic ones. Frequent descents, heavy loads, or wet/muddy conditions can shorten lifespan significantly.

How long do bike rim brake pads last?

Bike rim brake pads normally last about 1,000–3,000 km (620–1,860 miles), depending on rim material and riding environment. Wet or dirty conditions, especially on alloy rims, accelerate pad wear, while dry weather and smooth braking surfaces extend pad life.

How long do mountain bike brake pads last?

Mountain bike brake pads last 500–1,500 km (310–930 miles) due to frequent braking on steep, technical terrain, and exposure to mud, grit, and water. Sintered or semi-metallic pads are commonly used for their durability in rough conditions.

How long do road bike brake pads last?

Road bike brake pads last 1,500–3,000 km (930–1,860 miles) in dry, smooth conditions, especially with moderate braking. Resin pads wear faster, but carbon-specific pads for carbon rims may also need earlier replacement depending on heat buildup and rim wear.

Do bike brake pads get old?

Yes, bike brake pads get old because the pad material can degrade over time, even if unused, due to exposure to moisture, temperature changes, UV light, or contamination. Aged pads—especially resin or organic types—can become hard, brittle, or glazed, reducing braking efficiency, increasing noise, and potentially damaging the rotor or rim.

How much are bike brake pads?

Bike brake pads typically cost between USD 10–40 / EUR 10–35 / GBP 8–30, depending on the type (rim or disc), compound (resin, metallic, ceramic), and brand. Basic rim pads start around USD 10, while high-performance disc brake pads (e.g., sintered or ceramic for MTB or e-bikes) can reach up to USD 35–40 per pair.

What is the bike brake pad replacement cost?

Bike brake pad replacement cost typically ranges from USD 15–50 / EUR 15–45 / GBP 12–40, depending on the pad type, compound, and whether labor is included. Basic rim brake pads cost around USD 10–20, while high-performance disc brake pads (metallic or ceramic) range from USD 25–40, with professional installation adding USD 10–20.

What is the average cost to replace brake pads on a bike?

The average cost to replace brake pads is approximately USD 30 / EUR 28 / GBP 25 for parts and labor combined, making it a relatively low-cost yet essential maintenance task to ensure braking safety and performance.

Can old pads make bike brakes soft?

Yes, old brake pads can make bike brakes feel soft because the pad material may be worn down, glazed, or degraded, reducing the friction needed for firm braking. When pads are too thin or hardened over time, they can’t engage the rotor or rim effectively, resulting in a spongy lever feel and reduced stopping power.

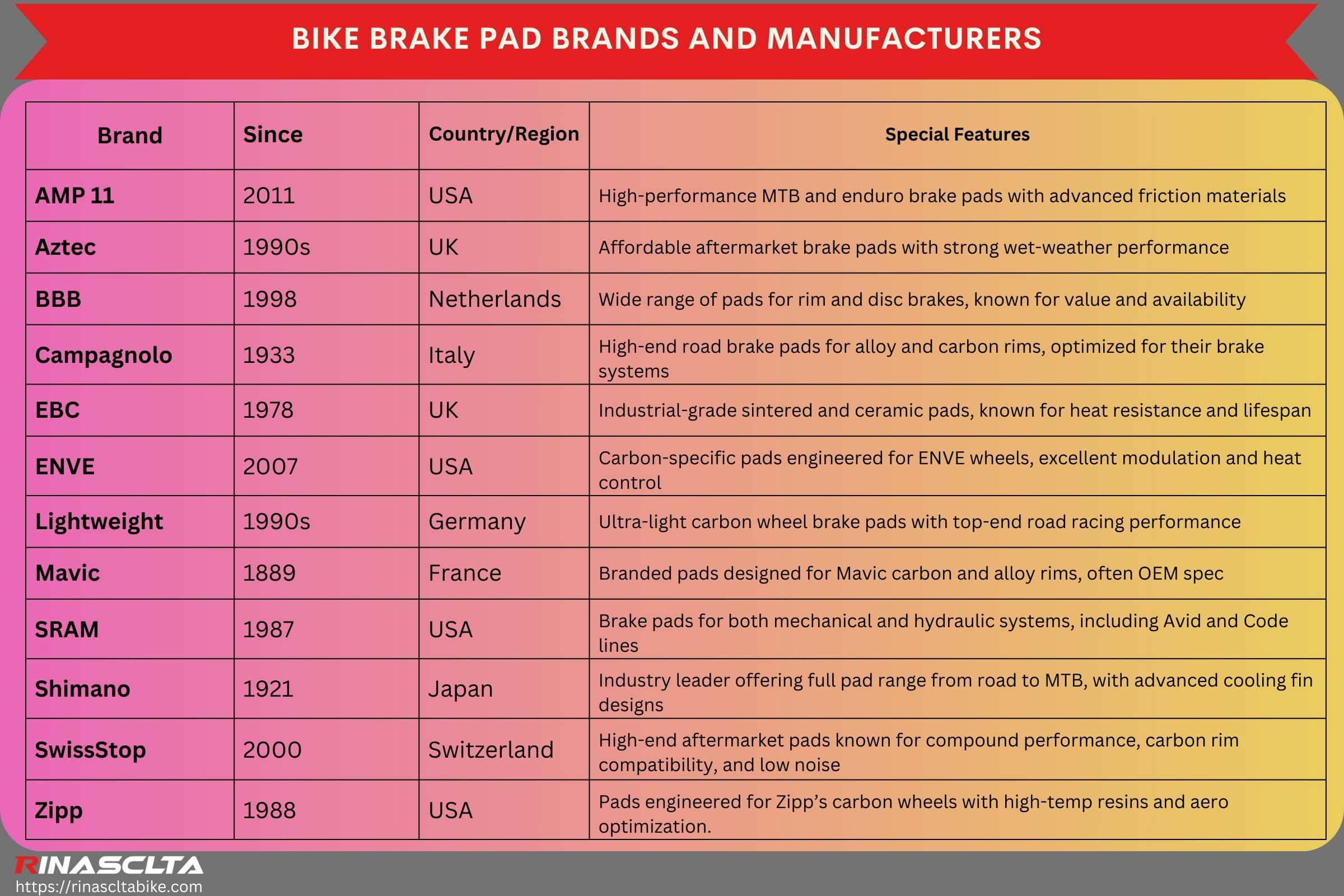

Bike brake pad brands and manufacturers

Bike brake pad brands and manufacturers have evolved to meet the increasing demands of modern cycling—from lightweight carbon road wheels to rugged mountain trails and high-speed e-bikes. These companies focus on developing brake pads with precise fit, material innovation, and performance tuning for specific brake systems and riding styles. Some brands like Shimano and SRAM dominate global OEM markets, while others like SwissStop, EBC, and Aztec specialize in advanced compounds for enhanced braking power, modulation, and heat resistance across diverse conditions.

| Brand | Since | Country/Region | Special Features |

| AMP 11 | 2011 | USA | High-performance MTB and enduro brake pads with advanced friction materials |

| Aztec | 1990s | UK | Affordable aftermarket brake pads with strong wet-weather performance |

| BBB | 1998 | Netherlands | Wide range of pads for rim and disc brakes, known for value and availability |

| Campagnolo | 1933 | Italy | High-end road brake pads for alloy and carbon rims, optimized for their brake systems |

| EBC | 1978 | UK | Industrial-grade sintered and ceramic pads, known for heat resistance and lifespan |

| ENVE | 2007 | USA | Carbon-specific pads engineered for ENVE wheels, excellent modulation and heat control |

| Lightweight | 1990s | Germany | Ultra-light carbon wheel brake pads with top-end road racing performance |

| Mavic | 1889 | France | Branded pads designed for Mavic carbon and alloy rims, often OEM spec |

| SRAM | 1987 | USA | Brake pads for both mechanical and hydraulic systems, including Avid and Code lines |

| Shimano | 1921 | Japan | Industry leader offering full pad range from road to MTB, with advanced cooling fin designs |

| SwissStop | 2000 | Switzerland | High-end aftermarket pads known for compound performance, carbon rim compatibility, and low noise |

| Zipp | 1988 | USA | Pads engineered for Zipp’s carbon wheels with high-temp resins and aero optimization. |