Bike rim is a crucial component of a bicycle wheel, forming the outer edge where the tire is mounted and playing a vital role in the overall performance, stability, and comfort of the bike. It works by providing a solid foundation for the tire, ensuring proper seating and inflation, and maintaining the structural integrity of the wheel. Bike rims are commonly made from materials such as aluminum and carbon fiber, each offering different benefits in terms of weight, strength, and durability.

In this article, we explain every type of bike rim, size, and expected lifespan of bike rims which help cyclists make informed decisions about their wheel setup and maintenance.

Table of Contents

What is a bike rim?

A bike rim is the outer part of a bicycle wheel that holds the tire in place and provides the necessary structure for the wheel to function properly. Typically bike rims are made from materials like aluminum or carbon fiber. Bike rims come in various types such as clincher, tubular, and tubeless, each offering different advantages in terms of weight, strength, and performance.

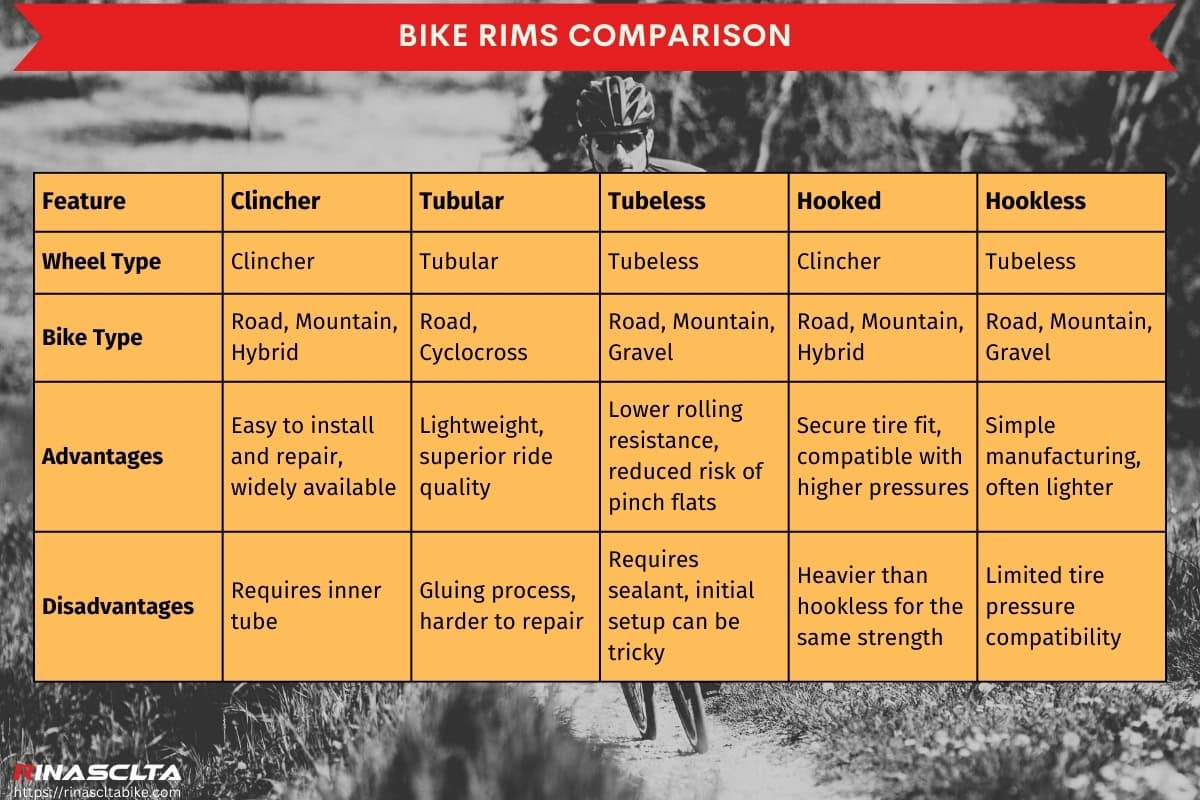

- Clincher: Clincher rims are the most common type, featuring a hooked edge that holds the tire bead in place, requiring an inner tube to maintain air pressure.

- Tubular: Tubular rims are designed for use with tubular tires, where the tire and tube are sewn together and glued directly onto the rim.

- Tubeless: Tubeless rims(Or tubeless ready) allow tires to be mounted with or without an inner tube, relying on an airtight seal between the tire and rim, often requiring sealant to prevent air leaks.

- Hooked: Hooked rims, also known as “bead seat” rims, have a small hook that secures the tire bead, commonly used with clincher tires.

- Hookless: Hookless rims have a straight inner wall without a hook, designed to work with tubeless tires, providing a more consistent tire bead interface.

| Feature | Clincher | Tubular | Tubeless | Hooked | Hookless |

| Wheel Type | Clincher | Tubular | Tubeless | Clincher | Tubeless |

| Bike Type | Road, Mountain, Hybrid | Road, Cyclocross | Road, Mountain, Gravel | Road, Mountain, Hybrid | Road, Mountain, Gravel |

| Advantages | Easy to install and repair, widely available | Lightweight, superior ride quality | Lower rolling resistance, reduced risk of pinch flats | Secure tire fit, compatible with higher pressures | Simple manufacturing, often lighter |

| Disadvantages | Requires inner tube | Gluing process, harder to repair | Requires sealant, initial setup can be tricky | Heavier than hookless for the same strength | Limited tire pressure compatibility |

Materials of bike rims

The materials of bike rims include aluminum for its balance of weight and durability and carbon fiber for its lightweight and high stiffness.

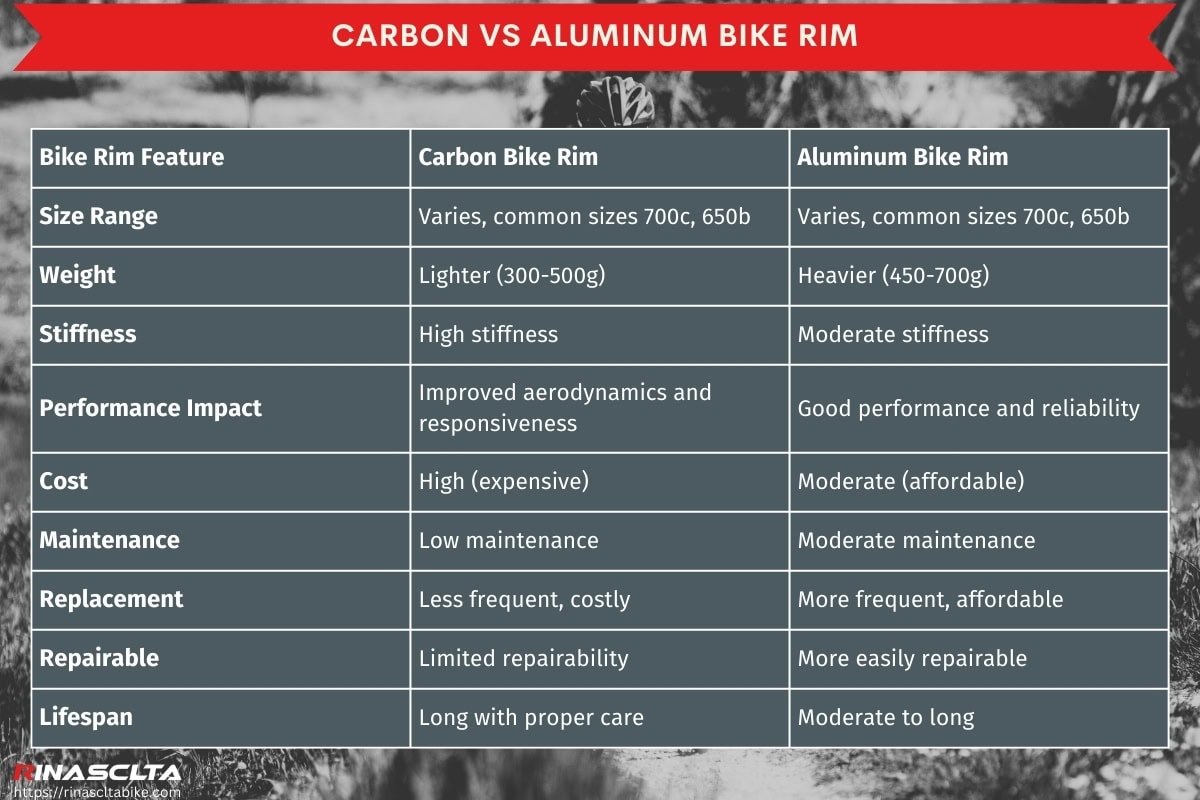

Carbon bike rim

Carbon bike rim is known for its lightweight and high stiffness, providing excellent aerodynamic performance and responsiveness, making it a premium choice for competitive cycling despite its higher cost compared to other materials.

Aluminum bike rim

Aluminum bike rim is valued for its balance of lightweight, durability, and affordability, offering good performance and reliability for both road and mountain biking, making it a popular choice among recreational and serious cyclists alike.

Carbon vs aluminum bike rim

Comparing carbon and aluminum bike rims helps cyclists understand the trade-offs between these two popular materials in terms of performance, cost, and durability.

| Bike Rim Feature | Carbon Bike Rim | Aluminum Bike Rim |

| Size Range | Varies, common sizes 700c, 650b | Varies, common sizes 700c, 650b |

| Weight | Lighter (300-500g) | Heavier (450-700g) |

| Stiffness | High stiffness | Moderate stiffness |

| Performance Impact | Improved aerodynamics and responsiveness | Good performance and reliability |

| Cost | High (expensive) | Moderate (affordable) |

| Maintenance | Low maintenance | Moderate maintenance |

| Replacement | Less frequent, costly | More frequent, affordable |

| Repairable | Limited repairability | More easily repairable |

| Lifespan | Long with proper care | Moderate to long |

Types of bike rims

There are various types of bike rims categorized by brake type (rim brake and disc brake), riding style (road, mountain, gravel, cyclocross, and BMX), and rim design (clincher, tubular, tubeless, hooked, and hookless), each designed to meet specific performance, durability, and compatibility needs for different cycling disciplines and preferences.

Bike rims by brake type

Bike rims are categorized by brake type to ensure compatibility with the braking system used on the bicycle, which directly affects the rim’s design and performance. The two main categories are rim brake bike rims, which are designed with a braking surface on the outer edge where the brake pads make contact to slow down the bike, and disc brake bike rims, which do not have a braking surface on the rim itself as braking is handled by a rotor attached to the hub, allowing for greater flexibility in rim construction and improved performance.

Rim brake bike rims

Rim brake bike rims are designed with a flat, smooth braking surface on the outer edge where the brake pads make contact to slow down the bike. Historically, rim brakes have been the standard for most bicycles, offering reliable performance for road bikes, commuter bikes, and older mountain bikes. Special features of rim brake rims include a precisely machined braking surface for consistent stopping power and the need for regular maintenance to ensure the brake pads and rim surface remain in good condition. Rim brake rims are typically lighter and simpler in design compared to disc brake rims, making them a popular choice for traditional and lightweight road bikes.

Disc brake bike rims

Disc brake bike rims are designed without the need for a braking surface on the rim itself, as braking is managed by a rotor attached to the wheel hub. Introduced more recently than rim brakes, disc brakes have become increasingly popular in mountain biking, cyclocross, gravel biking, and more recently, road biking due to their superior performance in wet and muddy conditions. Special features of disc brake rims include the ability to use wider tires without interference from brake calipers, increased stopping power, and reduced wear on the rims since the braking force is applied to the rotor. Disc brake rims are often more robust and can handle the higher stresses associated with off-road riding and intense braking.

Do disc brake bike rims last longer?

Yes, disc brake bike rims generally last longer because the braking force is applied to a separate rotor attached to the hub rather than the rim itself, reducing wear and tear on the rim surface and allowing the rim to maintain its structural integrity and performance over a longer period.

Can you convert a rim brake bike rim to disc brakes rim?

Yes, you can convert a rim brake bike rim to a disc brake rim if your bike frame and fork have the necessary mounting points for disc brake calipers and rotors, and you install a compatible wheel hub that supports disc brakes, as the rim itself does not impact the braking system.

Can you convert a disc brake bike rim to rim brake rim?

No, you cannot convert a disc brake bike rim to a rim brake rim because disc brake rims lack the machined braking surface required for rim brakes to function effectively and safely.

Are rim brake bikes dead?

No, rim brake bikes are not dead because they remain popular among many road cyclists and commuters due to their simplicity, lighter weight, and ease of maintenance, and they continue to be widely used and manufactured.

Bike rims by riding style type

Bike rims are categorized by riding style to ensure they meet the specific demands and performance requirements of different types of cycling. Road bike rims are designed to be lightweight and aerodynamic for speed on paved surfaces, making them the most popular among competitive cyclists. Gravel bike rims are versatile, accommodating wider tires for mixed terrain and providing a balance between durability and weight. Cyclocross rims are built to handle rough and muddy courses, offering robustness and good mud clearance. Mountain bike rims are strong and wide to support larger tires and withstand the impacts of off-road riding. Fat bike rims are even wider to accommodate extra-large tires for riding on snow, sand, and other soft surfaces. Heavy-duty bike rims are designed for carrying heavier loads, often used in touring and commuting bikes, providing extra strength and durability. This categorization ensures that each rim type is optimized for its intended use, enhancing performance, safety, and rider satisfaction.

Road bike rim

A road bike rim is designed to be lightweight and aerodynamic, optimizing speed and efficiency on paved surfaces. Historically, road bike rims have been a staple in competitive cycling and long-distance road biking due to their streamlined design and low weight. They are typically used on racing bikes, endurance bikes, and performance-oriented road bikes. Special features of road bike rims include a narrow profile to reduce air resistance, compatibility with high-pressure tires for reduced rolling resistance, and often a focus on minimal weight to improve climbing and acceleration.

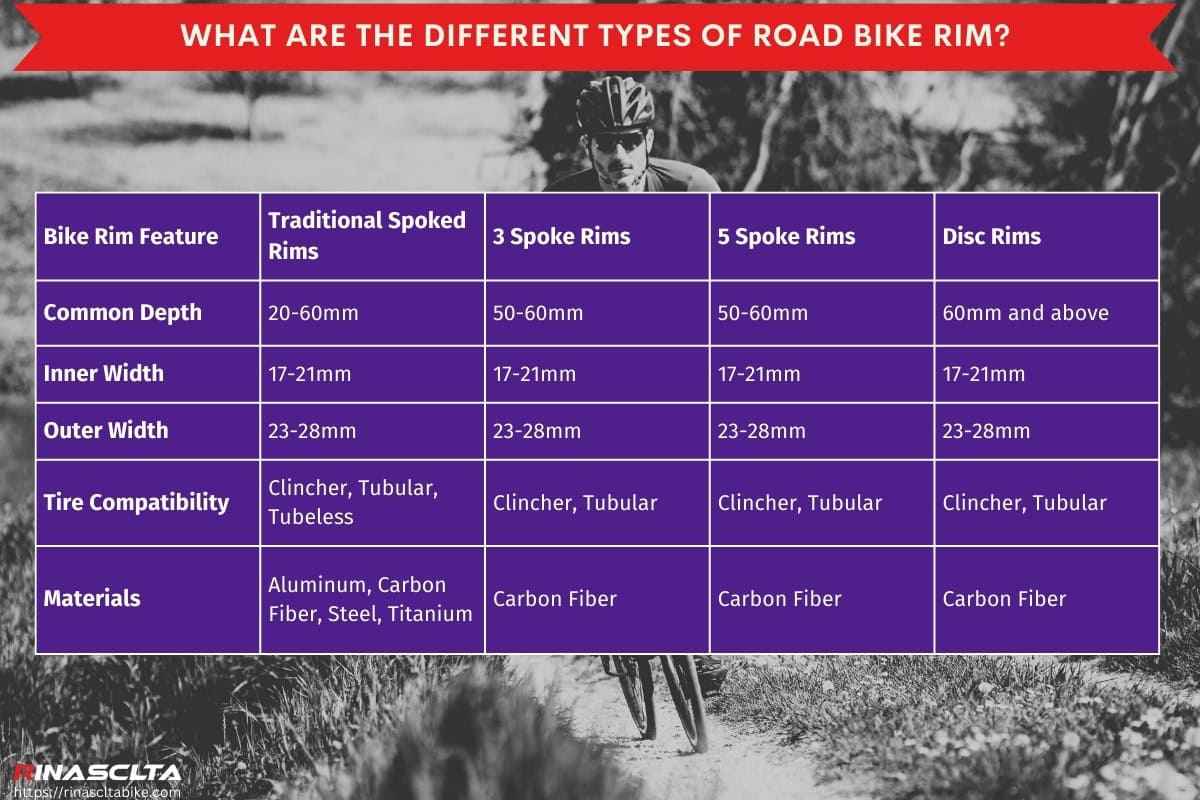

What are the different types of road bike rim?

Road bike rims come in various styles, depths, widths, and materials to cater to different riding needs and preferences. Here is a detailed overview of the different types of road bike rims:

Styles

- Traditional Spoked Rims: Classic design with multiple spokes (usually 20-32), providing a balance of weight, strength, and aerodynamics.

- 3 Spoke Rims: Aerodynamic design with three large spokes, often used in time trials and triathlons.

- 5 Spoke Rims: Similar to 3 spoke rims but with five spokes, offering a blend of aerodynamics and structural strength.

- Disc Rims: Solid disc design, highly aerodynamic, used primarily in time trials and track cycling.

Common Depth

- Shallow Depth (20-30mm): Lightweight and excellent for climbing, but less aerodynamic.

- Mid Depth (40-50mm): Offers a good balance between aerodynamics and weight.

- Deep Depth (60mm and above): Highly aerodynamic, best for flat terrain and time trials but heavier.

Inner and Outer Width

- Inner Width: Typically ranges from 17mm to 21mm, affecting tire stability and rolling resistance.

- Outer Width: Typically ranges from 23mm to 28mm, influencing overall tire profile and aerodynamics.

Tire Compatibility

- Clincher Rims: Compatible with clincher tires that use inner tubes; easy to repair and widely used.

- Tubular Rims: Designed for tubular tires that are glued onto the rim; favored by professional racers for their performance.

- Tubeless Rims: Allow tires to be mounted without inner tubes, offering lower rolling resistance and fewer flats.

Materials

- Aluminum: Common and affordable, offering a good balance of weight, strength, and cost.

- Carbon Fiber: Lightweight and stiff, providing superior performance and aerodynamics but at a higher cost.

- Steel: Less common, very durable, but heavier.

- Titanium: Rare, offers excellent strength-to-weight ratio and corrosion resistance.

| Bike Rim Feature | Traditional Spoked Rims | 3 Spoke Rims | 5 Spoke Rims | Disc Rims |

| Common Depth | 20-60mm | 50-60mm | 50-60mm | 60mm and above |

| Inner Width | 17-21mm | 17-21mm | 17-21mm | 17-21mm |

| Outer Width | 23-28mm | 23-28mm | 23-28mm | 23-28mm |

| Tire Compatibility | Clincher, Tubular, Tubeless | Clincher, Tubular | Clincher, Tubular | Clincher, Tubular |

| Materials | Aluminum, Carbon Fiber, Steel, Titanium | Carbon Fiber | Carbon Fiber | Carbon Fiber |

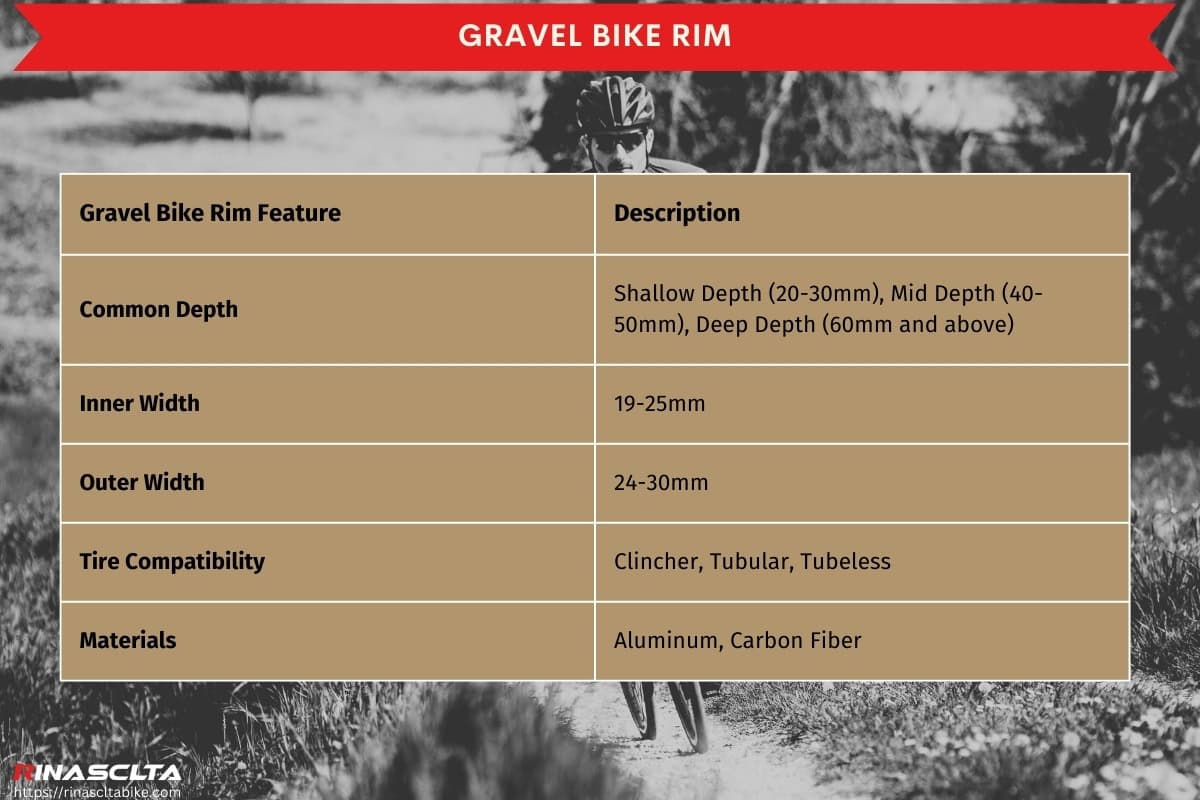

Gravel bike rim

A gravel bike rim is designed to handle the diverse conditions encountered in gravel riding, from smooth pavement to rough, unpaved roads and trails. Historically, gravel bike rims evolved from both road and mountain bike rims to meet the unique demands of gravel cycling, which requires durability, versatility, and the ability to accommodate wider tires. Gravel bike rims are typically used on gravel bikes, which are designed for adventure riding, bikepacking, and mixed-terrain cycling. Special features of gravel bike rims include reinforced construction for durability, wider profiles to support wider tires for better traction and comfort, and compatibility with various tire systems like clincher, tubular, and tubeless.

| Gravel Bike Rim Feature | Description |

| Common Depth | Shallow Depth (20-30mm), Mid Depth (40-50mm), Deep Depth (60mm and above) |

| Inner Width | 19-25mm |

| Outer Width | 24-30mm |

| Tire Compatibility | Clincher, Tubular, Tubeless |

| Materials | Aluminum, Carbon Fiber |

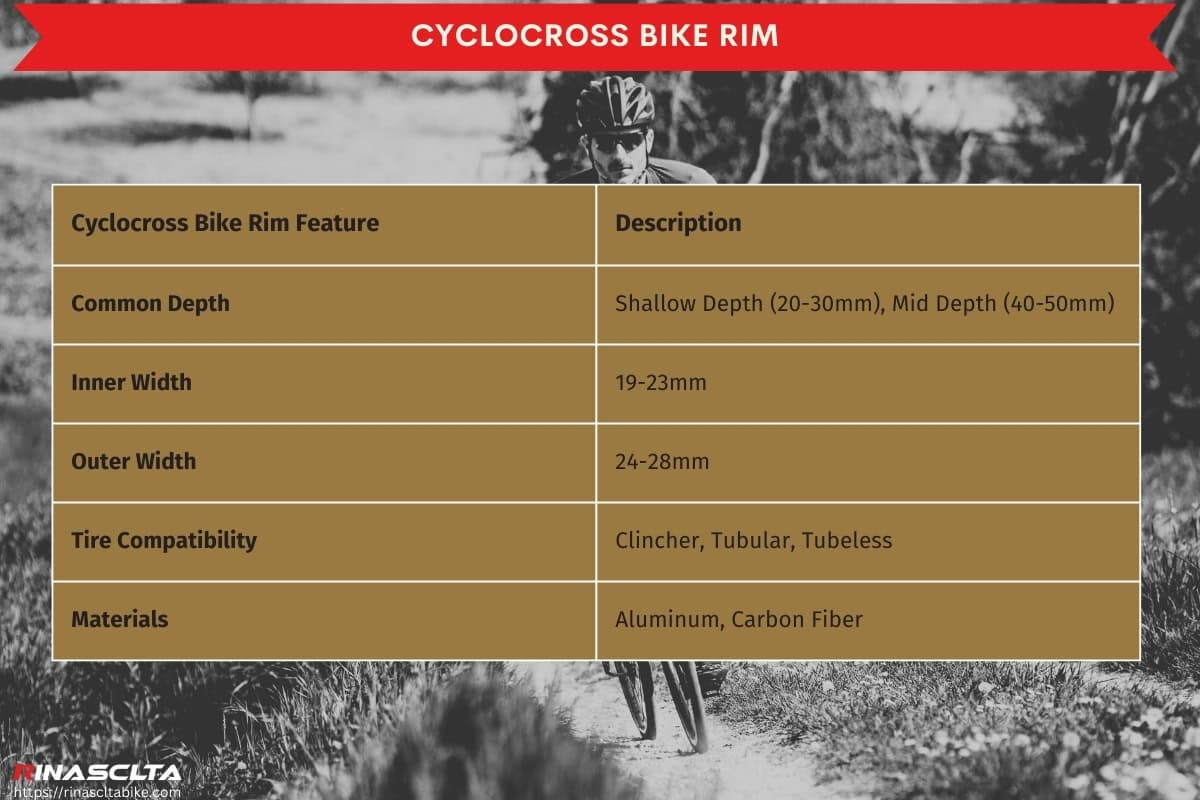

Cyclocross bike rim

A cyclocross bike rim is designed specifically for the rigors of cyclocross racing, which involves a mix of pavement, trails, grass, and mud, with frequent obstacles that require the rider to dismount and carry the bike. Historically, cyclocross rims have evolved from road bike rims to meet the unique demands of the sport, which requires lightweight yet durable construction, excellent mud clearance, and the ability to accommodate wider tires for better grip and control. Cyclocross rims are typically used on cyclocross bikes, designed for both racing and training in varied conditions. Special features of cyclocross rims include reinforced construction for durability, a focus on mud-shedding capabilities, and compatibility with different tire systems like clincher, tubular, and tubeless.

| Cyclocross Bike Rim Feature | Description |

| Common Depth | Shallow Depth (20-30mm), Mid Depth (40-50mm) |

| Inner Width | 19-23mm |

| Outer Width | 24-28mm |

| Tire Compatibility | Clincher, Tubular, Tubeless |

| Materials | Aluminum, Carbon Fiber |

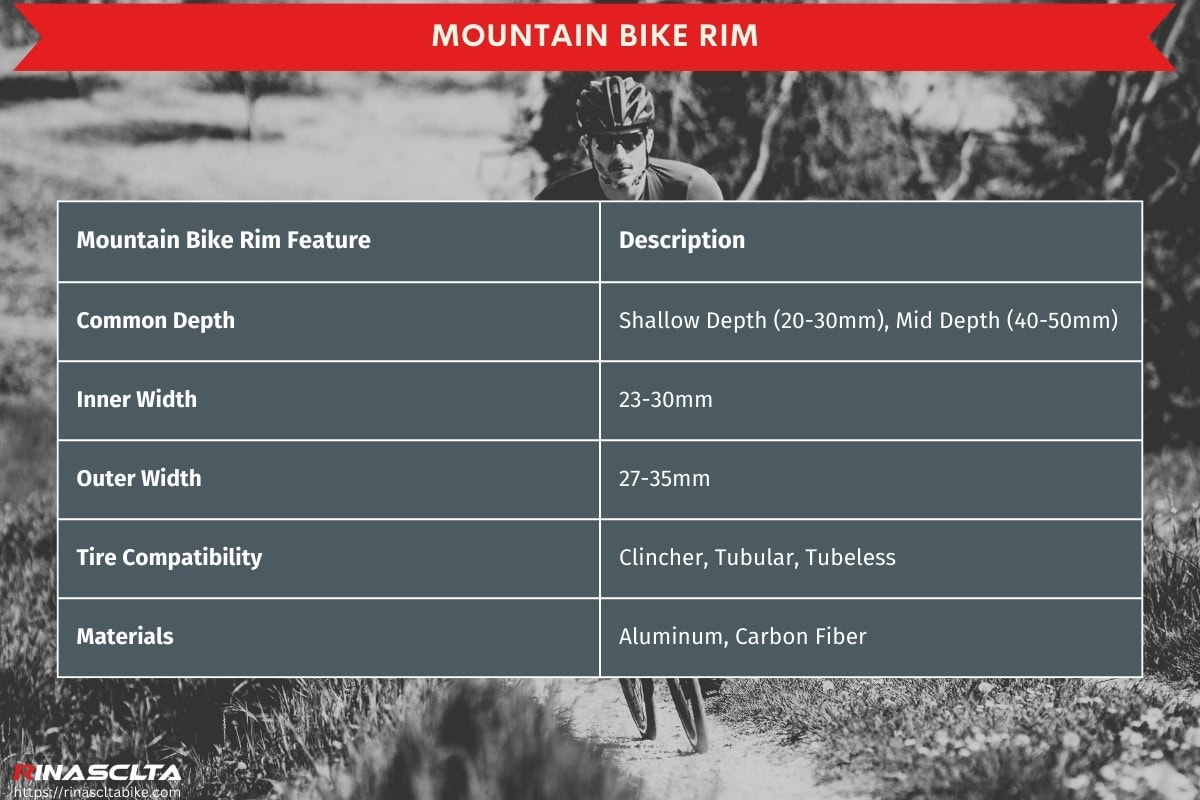

Mountain bike rim

A mountain bike rim is specifically designed to withstand the harsh conditions and rough terrain encountered in mountain biking, providing durability, strength, and performance. Historically, mountain bike rims have evolved from road bike rims to meet the demands of off-road cycling, which requires wider rims for better tire support, reinforced construction for impact resistance, and compatibility with lower tire pressures for improved traction. Mountain bike rims are used on mountain bikes, which are designed for trail riding, downhill racing, cross-country, and enduro. Special features of mountain bike rims include wider profiles to support larger tires, tubeless compatibility for reducing flats and running lower pressures, and reinforced materials to handle impacts and rough terrain.

| Mountain Bike Rim Feature | Description |

| Common Depth | Shallow Depth (20-30mm), Mid Depth (40-50mm) |

| Inner Width | 23-30mm |

| Outer Width | 27-35mm |

| Tire Compatibility | Clincher, Tubular, Tubeless |

| Materials | Aluminum, Carbon Fiber |

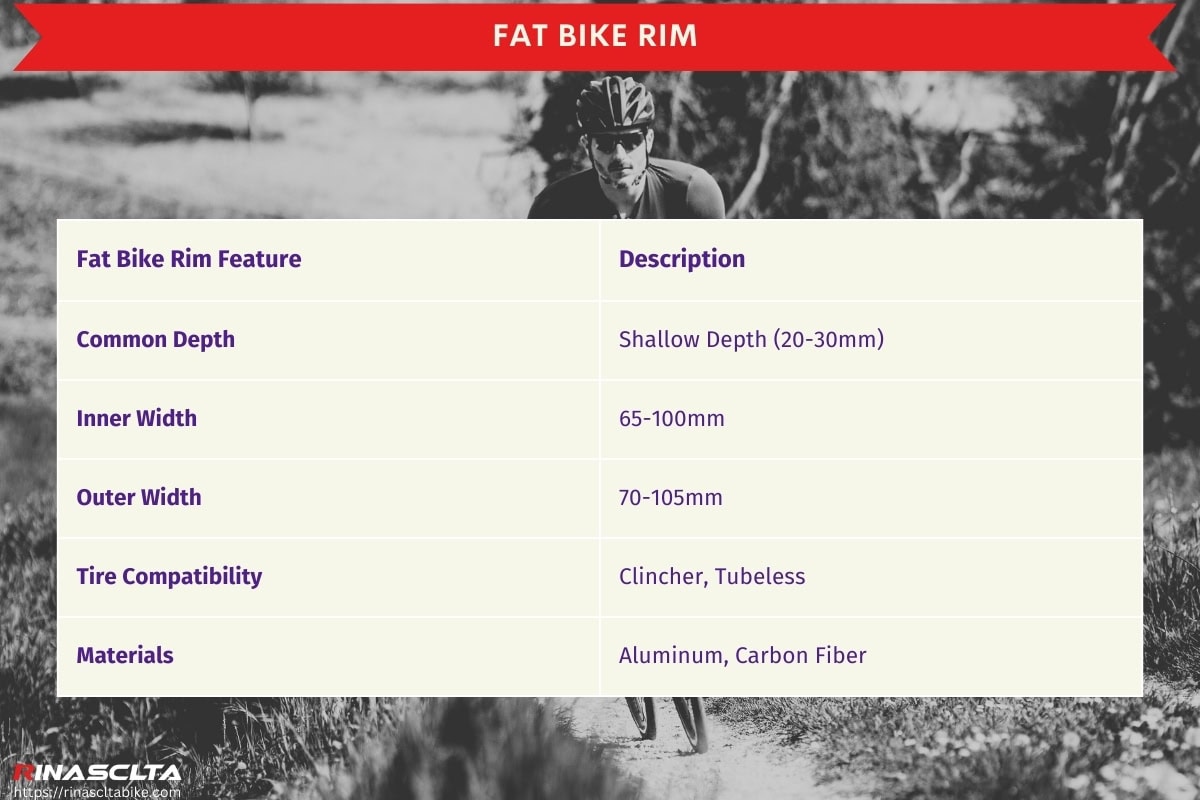

Fat bike rim

A fat bike rim is designed to accommodate the extra-wide tires used in fat biking, which are intended for riding on soft, unstable surfaces such as snow, sand, and mud. Historically, fat bike rims evolved to meet the needs of cyclists looking for greater flotation and traction in conditions where traditional mountain bike tires would sink or slip. Fat bike rims are used on fat bikes, which are specialized bicycles designed for extreme terrain and adverse conditions. Special features of fat bike rims include significantly wider profiles to support tires ranging from 3.8 to 5 inches in width, the ability to run very low tire pressures for maximum traction, and often tubeless compatibility to further enhance performance and reduce the risk of flats.

| Fat Bike Rim Feature | Description |

| Common Depth | Shallow Depth (20-30mm) |

| Inner Width | 65-100mm |

| Outer Width | 70-105mm |

| Tire Compatibility | Clincher, Tubeless |

| Materials | Aluminum, Carbon Fiber |

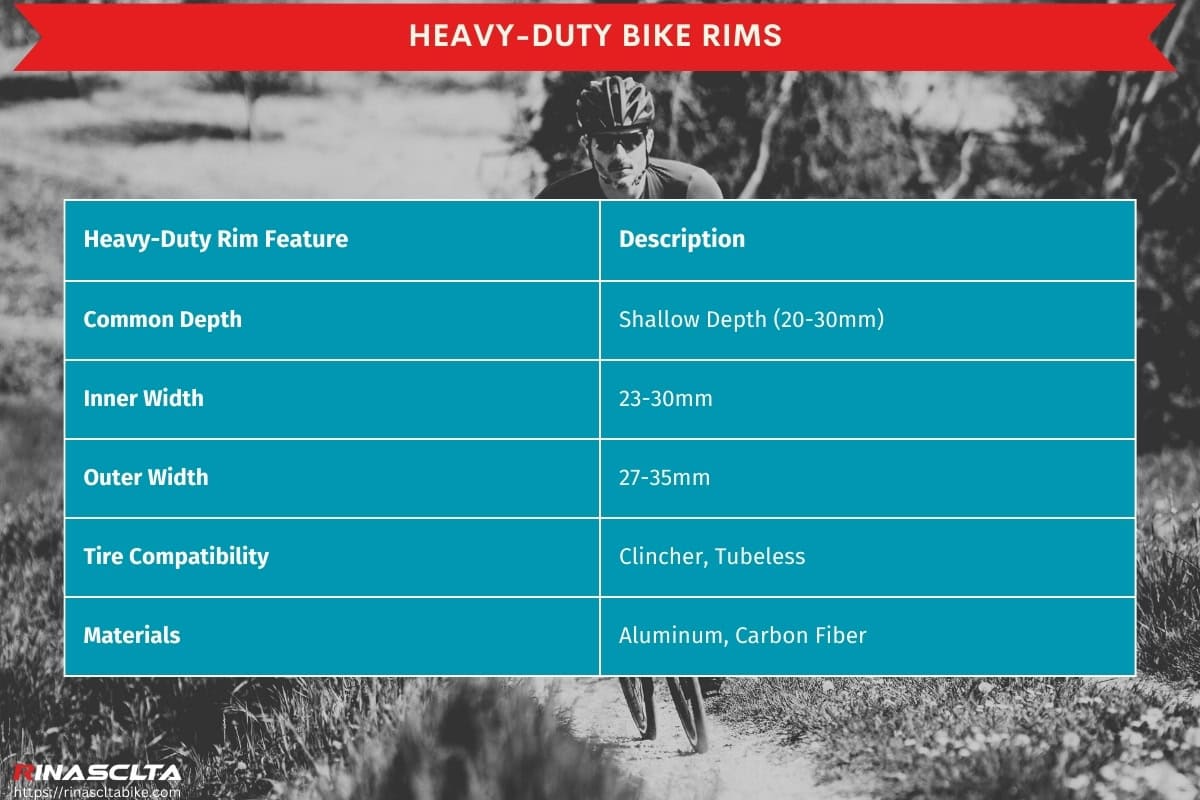

Heavy-duty bike rims

Heavy-duty bike rims are specifically designed to handle greater loads and more demanding conditions than standard bike rims, often used on touring bikes, commuter bikes, and cargo bikes. Historically, heavy-duty rims have been developed to provide enhanced strength and durability for riders who carry heavy loads or ride in challenging environments. Special features of heavy-duty rims include reinforced construction, wider profiles for stability, and compatibility with various tire types

| Heavy-Duty Rim Feature | Description |

| Common Depth | Shallow Depth (20-30mm) |

| Inner Width | 23-30mm |

| Outer Width | 27-35mm |

| Tire Compatibility | Clincher, Tubeless |

| Materials | Aluminum, Carbon Fiber |

Are wider bike rims better?

No, wider bike rims are not necessarily better because they can increase weight and rolling resistance, which might not be desirable for all types of riding; however, they are beneficial when riding on rough or loose terrain as they provide better tire stability, increased traction, and improved comfort.

Can any bike rim be converted to a tubeless rim?

No, not any bike rim can be converted to a tubeless rim because not all rims are designed to create an airtight seal necessary for tubeless tires; however, conversion is possible when the rim has a compatible bead hook and a secure fit for the tubeless tire, and is reinforced to handle the lower pressures typically used in tubeless setups.

Are all bike rims tubeless-ready?

No, not all bike rims are tubeless-ready because they may lack the necessary bead hooks and airtight seals required for tubeless tire installation; only rims specifically designed and labeled as tubeless-ready are built to ensure a secure and airtight fit for tubeless tires.

Bike rim by design type

Bike rims are categorized by design type to optimize wheel performance, balance, and strength based on the spoke hole placement. Asymmetric bike rims have offset spoke holes that help equalize spoke tension between the drive and non-drive sides of the wheel, improving strength and durability. This design works by distributing the load more evenly across the wheel, which can enhance overall performance and reduce the risk of spoke breakage. Symmetric bike rims, on the other hand, have centered spoke holes, making them easier to build and more common, especially in traditional road and mountain bikes. Asymmetric rims are becoming increasingly popular in performance-focused applications due to their advantages in durability and spoke tension balance, while symmetric rims remain the standard for many general-purpose bikes due to their simplicity and ease of use.

Asymmetric bike rims

Asymmetric bike rims are designed with the spoke holes offset from the centerline of the rim. This design aims to balance the spoke tension between the drive side and the non-drive side of the wheel. In a traditional symmetric wheel, the spoke tension is often higher on the drive side due to the space taken up by the cassette or brake rotor, leading to uneven stress distribution.

- Design: The spoke holes are strategically placed closer to one edge of the rim, shifting the spokes outward on the drive side and inward on the non-drive side. This results in a more balanced spoke tension across the wheel.

- Purpose: The primary purpose of asymmetric rims is to enhance wheel durability and strength by evening out spoke tension. This reduces the likelihood of spoke breakage and improves the wheel’s overall lifespan.

- Performance: Asymmetric rims provide a more robust and reliable wheel build, which is particularly beneficial for heavy-duty applications like mountain biking, cyclocross, and gravel riding. The improved spoke tension balance also enhances the wheel’s stiffness and responsiveness.

- Weight: Asymmetric rims can be slightly heavier than symmetric rims due to the additional material used to offset the spoke holes. However, advancements in materials and design have minimized this weight difference, making asymmetric rims a viable option for performance-oriented cyclists.

- Overall Benefits: The balanced spoke tension in asymmetric rims leads to a stronger, more durable wheel that can better withstand the rigors of demanding riding conditions. This design is becoming increasingly popular among cyclists who prioritize performance and reliability.

Symmetric bike rims

Symmetric bike rims are designed with the spoke holes centered along the middle of the rim’s width, creating an evenly distributed spoke pattern on both sides of the wheel. This traditional design is straightforward and has been the standard for most bicycles for many years.

- Design: The spoke holes are evenly spaced and aligned along the centerline of the rim. This design does not compensate for the different angles of the spokes on the drive and non-drive sides of the wheel, leading to different spoke tensions on each side.

- Purpose: Symmetric rims are designed for simplicity and ease of manufacturing and wheel building. They are suitable for a wide range of cycling applications, from road and mountain biking to commuting and recreational riding.

- Performance: While symmetric rims are easier to build and maintain, the uneven spoke tension between the drive side (often under higher tension due to the cassette or disc brake rotor) and the non-drive side can lead to a less balanced wheel. This can make the wheel slightly less durable and more prone to needing adjustments over time compared to asymmetric rims.

- Weight: Symmetric rims are typically lightweight because they do not require the additional material needed to offset the spoke holes, as seen in asymmetric designs. This makes them a preferred choice for cyclists looking to minimize bike weight.

- Overall Benefits: The main advantages of symmetric rims are their simplicity, ease of use, and lower cost. They are widely used and remain popular for most general cycling needs, providing reliable performance without the complexities of asymmetric designs. However, for high-stress applications or competitive cycling, riders might opt for asymmetric rims to gain the benefits of balanced spoke tension and enhanced durability.

How to measure bike rim size?

To measure bike rim size accurately, you need to consider several key dimensions: the rim diameter, inner width, outer width, and depth. Here’s how you can measure each of these:

- Rim Diameter: Measure the diameter of the rim from bead seat to bead seat (the part of the rim where the tire bead sits). This is typically done using a tape measure and is measured in millimeters or inches.

- Inner Width: Measure the width of the rim from the inside edges where the tire bead sits, usually using a caliper for precision. This width impacts the tire fit and performance.

- Outer Width: Measure the total width of the rim from the outermost points. This affects the tire’s overall profile and aerodynamics.

- Rim Depth: Measure the height of the rim from the tire bed to the outer edge. This impacts the aerodynamics and weight of the wheel.

- Dynamo: Refers to a built-in hub dynamo which can affect the rim’s design and weight.

- ERD (Effective Rim Diameter): This is the diameter at which the ends of the spokes sit in the rim. It’s crucial for determining the correct spoke length.

- Flat Spot: A flat spot on the rim indicates damage or deformation, which can affect the wheel’s performance and safety.

- Offset: The spoke holes are drilled offset from the centerline to balance spoke tension. This is common in asymmetric rims.

To measure these dimensions, use a combination of tape measures for length and calipers for precision in width. Make sure to note all measurements in either millimeters or inches for consistency. Properly measuring these aspects of a rim ensures the right fit and performance for your specific biking needs.

Bike rim diameter chart

Below is the bike rim diameter chart for 650B/27.5″ rim, 700C/29″ rim and 26″ rim.

Bike rim diagram

Below is the bike rim diagram for different rim types like 26″/27.5″/29″ MTB rim, and 38/50/60 road bike rim.

Bike rim parts names

Bike rim parts include the bead seat, sidewalls, spoke holes, nipple bed, brake track (for rim brakes), and valve hole.

How to find out rim size on a bike wheel?

To find out the rim size on a bike wheel, check for stickers or engravings on the rim itself that typically display the size information, refer to the manufacturer’s brand and model information on the rim, or visit the brand’s website for detailed specifications based on the model number.

What is 700c bike rim size?

A 700c bike rim size refers to a rim with an outer diameter of approximately 622 millimeters (24.5 inches), commonly used for road, cyclocross, and hybrid bikes, and is designed to fit tires with diameters that provide a standard overall wheel size of 700 millimeters.

What is 650b rim size?

A 650b (27.5″) rim size refers to a rim with an outer diameter of approximately 584 millimeters (23 inches), commonly used for mountain, gravel, and adventure bikes, providing a balance between the agility of 26″ wheels and the rollover capability of 29″ wheels.

What is 29” rim size?

A 29” rim size refers to a rim with an outer diameter of approximately 622 millimeters (24.5 inches), the same as a 700c rim, but typically designed to accommodate wider tires, making it popular for mountain biking due to its superior rollover capability and traction.

Bike tire width vs rim width, how to choose?

Choosing the correct tire width for a given rim width is crucial for optimal performance, safety, and comfort. The compatibility between tire and rim width affects the tire’s shape, pressure, and overall riding experience. Below is a comparison table that shows the recommended tire widths for various rim widths, considering different types of bikes such as road bikes and mountain bikes.

| Inner Rim Width (mm) | Outer Rim Width (mm) | Recommended Tire Width (mm) | Recommended Tire Width (inch) | Bike Type |

| 13-15 mm | 18-20 mm | 23-25 mm | 0.91-0.98 inch | Road Bike |

| 17-19 mm | 22-24 mm | 25-32 mm | 0.98-1.26 inch | Road Bike |

| 20-24 mm | 25-29 mm | 30-45 mm | 1.18-1.77 inch | Gravel/Cyclocross |

| 25-30 mm | 30-35 mm | 45-50 mm | 1.77-1.97 inch | Gravel/Cyclocross |

| 30-35 mm | 35-40 mm | 50-60 mm | 1.97-2.36 inch | Mountain Bike |

| 35-40 mm | 40-45 mm | 60-75 mm | 2.36-2.95 inch | Mountain Bike |

| 40+ mm | 45+ mm | 75-100 mm | 2.95-3.94 inch | Fat Bike |

Do road tires fit mountain bike rims?

No, road tires do not fit mountain bike rims because mountain bike rims are typically wider and designed to accommodate larger tires with different bead diameters and pressures; however, some hybrid rims might fit both types but generally at the cost of performance and safety.

Are all road bike rims the same size?

No, all road bike rims are not the same size because they vary in depth, width, and diameter to cater to different types of road cycling such as racing, endurance, and touring, which require specific rim dimensions for optimal performance.

Do different bike tires need different rims?

Yes, different bike tires need different rims if they vary significantly in width and bead diameter because rims are designed to match specific tire profiles to ensure proper fit, safety, and performance; however, some rims can accommodate a range of tire sizes within certain limits.

Can I put a wider tire on my bike rim?

Yes, you can put a wider tire on your bike rim if the rim’s inner width supports the tire width and your bike frame has enough clearance; however, going too wide can negatively impact handling and performance and may not fit properly on the rim.

Can you put different width tires on the same rim bike?

Yes, you can put different width tires on the same rim bike if the rim and frame clearance allow for the range of widths; however, each tire width change can affect the bike’s handling, performance, and fit, so it is important to stay within the manufacturer’s recommended range.

Do road tires fit mountain bike rims?

No, road tires do not fit mountain bike rims because mountain bike rims are generally wider and designed for larger tires with different bead standards and lower pressures, making it impractical and unsafe to fit narrow road tires on them.

How long do bike rims last?

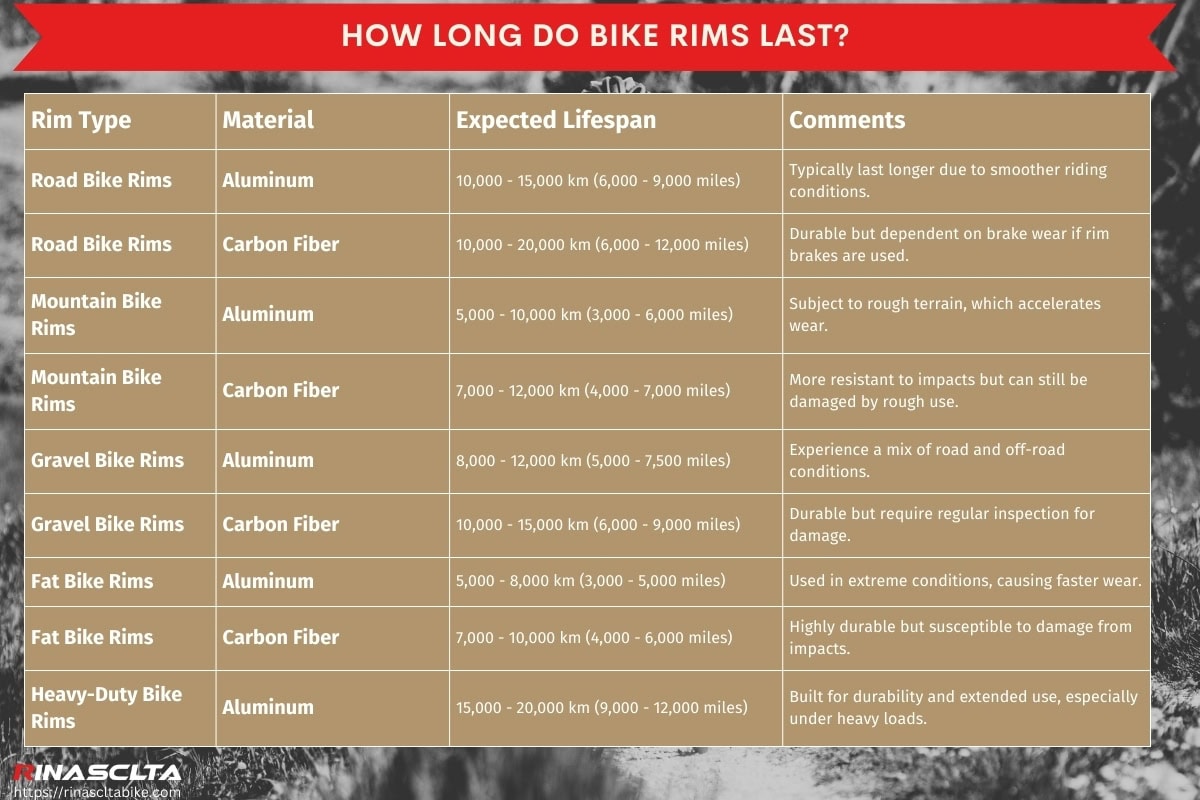

Bike rims have a varied lifespan depending on the type of riding, material, and maintenance. Generally, road bike rims, mountain bike rims, and other specific types have different expected lifespans.

Bike rims can last anywhere from 5,000 to 15,000 kilometers (3,000 to 9,000 miles) or about 2 to 5 years, depending on the type of riding, material, and maintenance. Road bike rims tend to last longer due to less harsh conditions, while mountain bike rims may require more frequent replacement due to rough terrain. Here is a detailed breakdown below table.

| Rim Type | Material | Expected Lifespan | Comments |

| Road Bike Rims | Aluminum | 10,000 – 15,000 km (6,000 – 9,000 miles) | Typically last longer due to smoother riding conditions. |

| Road Bike Rims | Carbon Fiber | 10,000 – 20,000 km (6,000 – 12,000 miles) | Durable but dependent on brake wear if rim brakes are used. |

| Mountain Bike Rims | Aluminum | 5,000 – 10,000 km (3,000 – 6,000 miles) | Subject to rough terrain, which accelerates wear. |

| Mountain Bike Rims | Carbon Fiber | 7,000 – 12,000 km (4,000 – 7,000 miles) | More resistant to impacts but can still be damaged by rough use. |

| Gravel Bike Rims | Aluminum | 8,000 – 12,000 km (5,000 – 7,500 miles) | Experience a mix of road and off-road conditions. |

| Gravel Bike Rims | Carbon Fiber | 10,000 – 15,000 km (6,000 – 9,000 miles) | Durable but require regular inspection for damage. |

| Fat Bike Rims | Aluminum | 5,000 – 8,000 km (3,000 – 5,000 miles) | Used in extreme conditions, causing faster wear. |

| Fat Bike Rims | Carbon Fiber | 7,000 – 10,000 km (4,000 – 6,000 miles) | Highly durable but susceptible to damage from impacts. |

| Heavy-Duty Bike Rims | Aluminum | 15,000 – 20,000 km (9,000 – 12,000 miles) | Built for durability and extended use, especially under heavy loads. |

How long do road bike rims last?

Road bike rims typically last between 10,000 to 20,000 kilometers (6,000 to 12,000 miles), depending on the material and riding conditions, with aluminum rims generally lasting 10,000 to 15,000 kilometers and carbon fiber rims lasting 10,000 to 20,000 kilometers, assuming regular maintenance and proper use.

How long do mountain bike rims last?

Mountain bike rims generally last between 5,000 to 12,000 kilometers (3,000 to 7,500 miles), with aluminum rims typically lasting 5,000 to 10,000 kilometers and carbon fiber rims lasting 7,000 to 12,000 kilometers, depending on terrain and riding conditions.

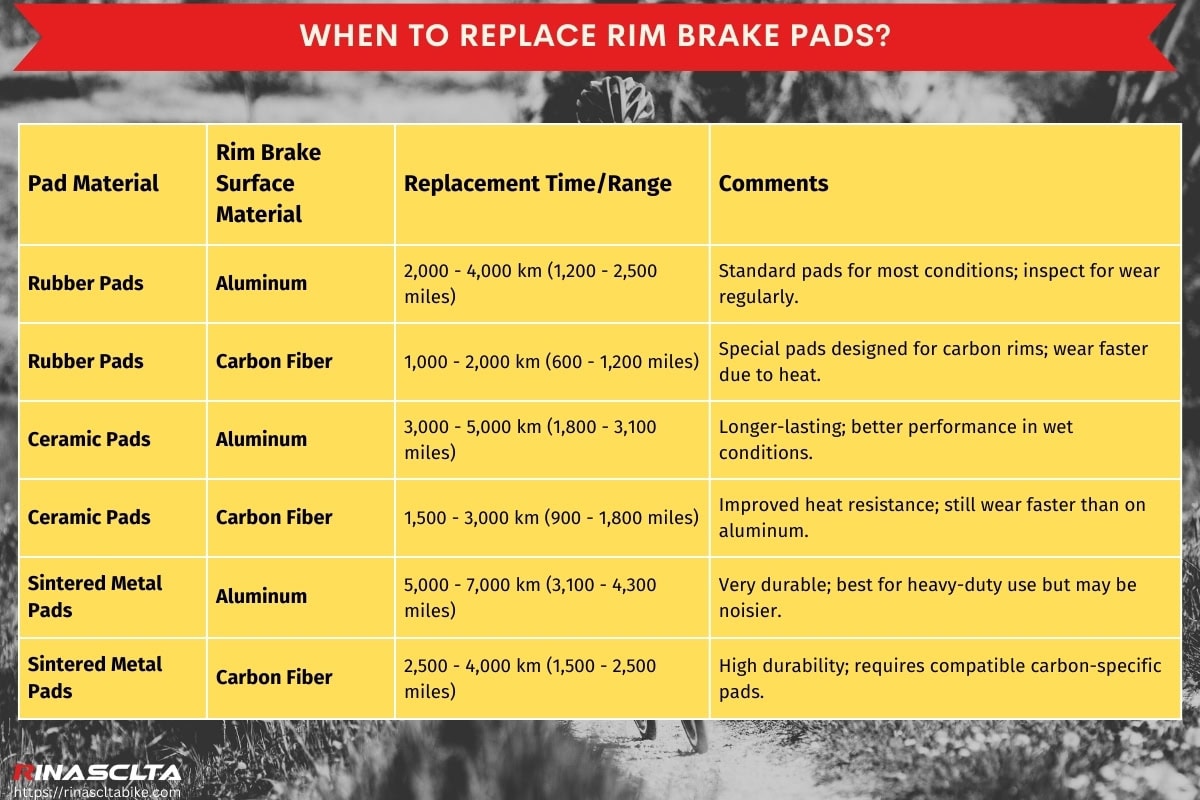

When to replace rim brake pads?

Rim brake pads wear out over time due to friction against the rim, which is necessary for stopping the bike. The time to replace them varies based on factors such as pad material, rim material, riding conditions, and frequency of use. Regular inspection is essential to ensure brake efficiency and safety. Rim brake pads should be checked regularly for wear, especially before long rides or in harsh weather conditions. Look for grooves, cracks, or significant wear on the pad surface, and replace them if they are worn down to the wear indicator line or if braking performance decreases.

| Pad Material | Rim Brake Surface Material | Replacement Time/Range | Comments |

| Rubber Pads | Aluminum | 2,000 – 4,000 km (1,200 – 2,500 miles) | Standard pads for most conditions; inspect for wear regularly. |

| Rubber Pads | Carbon Fiber | 1,000 – 2,000 km (600 – 1,200 miles) | Special pads designed for carbon rims; wear faster due to heat. |

| Ceramic Pads | Aluminum | 3,000 – 5,000 km (1,800 – 3,100 miles) | Longer-lasting; better performance in wet conditions. |

| Ceramic Pads | Carbon Fiber | 1,500 – 3,000 km (900 – 1,800 miles) | Improved heat resistance; still wear faster than on aluminum. |

| Sintered Metal Pads | Aluminum | 5,000 – 7,000 km (3,100 – 4,300 miles) | Very durable; best for heavy-duty use but may be noisier. |

| Sintered Metal Pads | Carbon Fiber | 2,500 – 4,000 km (1,500 – 2,500 miles) | High durability; requires compatible carbon-specific pads. |

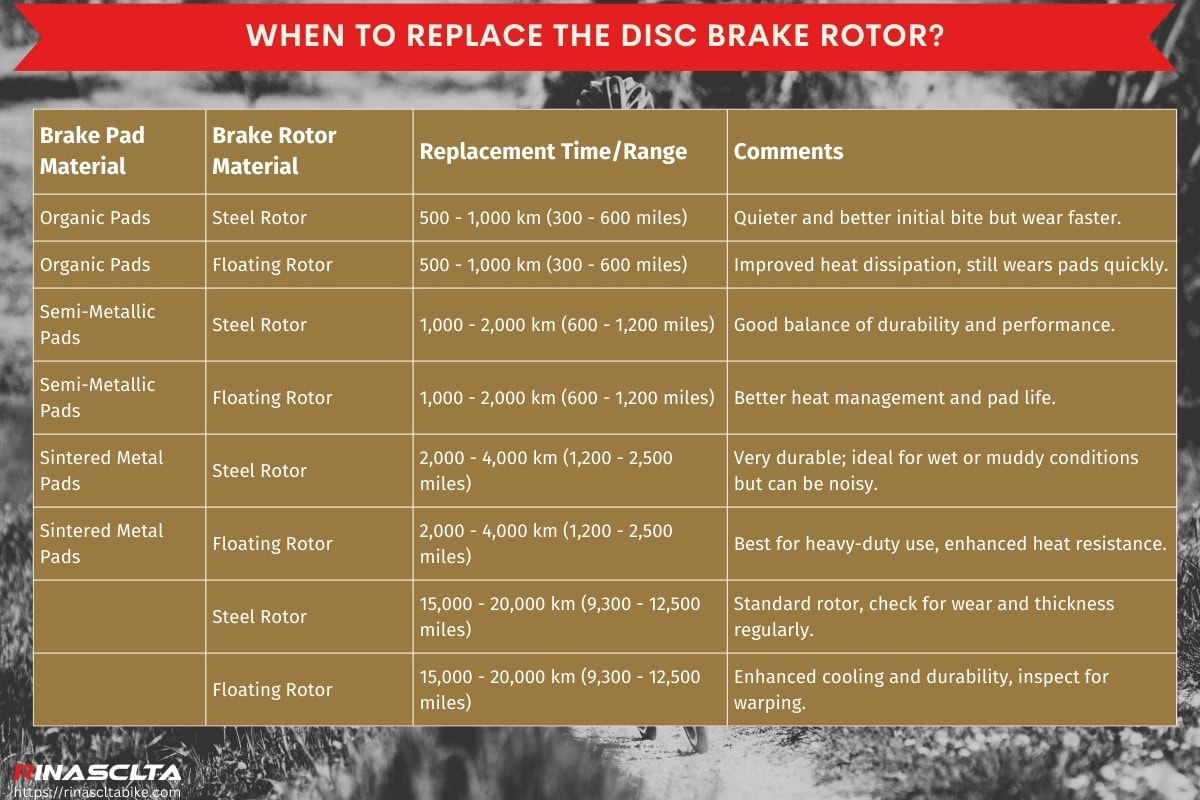

When to replace the disc brake rotor?

Disc brake pads and rotors wear out over time due to the friction and heat generated during braking. The replacement time varies based on factors such as pad material, rotor material, riding conditions, and frequency of use. Regular inspection is essential to ensure optimal braking performance and safety. Disc brake pads and rotors should be regularly inspected for signs of wear. Brake pads should be replaced if they are worn down to 1 mm of pad material or if braking performance decreases. Rotors should be replaced if they become warped, excessively worn, or if their thickness falls below the manufacturer’s minimum specification. Regular maintenance ensures reliable braking performance and extends the life of the braking system.

| Brake Pad Material | Brake Rotor Material | Replacement Time/Range | Comments |

| Organic Pads | Steel Rotor | 500 – 1,000 km (300 – 600 miles) | Quieter and better initial bite but wear faster. |

| Organic Pads | Floating Rotor | 500 – 1,000 km (300 – 600 miles) | Improved heat dissipation, still wears pads quickly. |

| Semi-Metallic Pads | Steel Rotor | 1,000 – 2,000 km (600 – 1,200 miles) | Good balance of durability and performance. |

| Semi-Metallic Pads | Floating Rotor | 1,000 – 2,000 km (600 – 1,200 miles) | Better heat management and pad life. |

| Sintered Metal Pads | Steel Rotor | 2,000 – 4,000 km (1,200 – 2,500 miles) | Very durable; ideal for wet or muddy conditions but can be noisy. |

| Sintered Metal Pads | Floating Rotor | 2,000 – 4,000 km (1,200 – 2,500 miles) | Best for heavy-duty use, enhanced heat resistance. |

| Steel Rotor | 15,000 – 20,000 km (9,300 – 12,500 miles) | Standard rotor, check for wear and thickness regularly. | |

| Floating Rotor | 15,000 – 20,000 km (9,300 – 12,500 miles) | Enhanced cooling and durability, inspect for warping. |

How to true a bike rim?

To true a bike rim, follow these steps using a truing stand, spoke wrench, and a tension meter for precision.

- Mount the Wheel: Place the wheel in a truing stand and secure it properly. If you don’t have a truing stand, you can use the bike frame by flipping the bike upside down and using the brake pads as a reference point.

- Identify the Wobble: Spin the wheel and observe the rim’s movement. Note where the rim deviates to the left or right.

- Locate the Spokes: Identify the spokes near the deviation. For a leftward wobble, you’ll need to tighten the spokes on the right side (opposite the wobble) and vice versa.

- Adjust Spoke Tension: Use a spoke wrench to turn the nipple of the spoke. Tighten the spoke by turning the nipple clockwise and loosen by turning it counterclockwise. Make small adjustments, typically a quarter turn at a time.

- Check Vertical True: Ensure the rim does not have vertical deviations (up and down movement). Adjust the spoke tension similarly by tightening the spokes at the high spots and loosening at the low spots.

- Recheck the Wheel: Spin the wheel again and observe the changes. Repeat the process until the rim runs true both horizontally and vertically.

- Check Spoke Tension: Use a tension meter to ensure that the spoke tension is even throughout the wheel. Adjust as necessary to achieve uniform tension.

- Final Adjustments: Make fine adjustments to the spokes to perfect the true of the wheel. Ensure all spokes are adequately tensioned without any being overly tight or loose.

By following these steps, you can true a bike rim, ensuring it runs straight and true, which improves riding performance and safety. Regular truing and maintenance can extend the life of your wheels and provide a smoother ride.

How to fix a bent bike rim?

To fix a bent bike rim, use a spoke wrench to adjust the tension of the spokes adjacent to the bend, tighten the spokes on the opposite side of the bend, and loosen the spokes on the side until the rim is straight. If the bend is severe, gently apply pressure to the rim with your hands or a rubber mallet to reshape it before fine-tuning with spokes adjustments.

How to straighten a bike rim?

To straighten a bike rim, use a truing stand and a spoke wrench to adjust the tension of the spokes near the deviation, tightening spokes on the side opposite the wobble and loosening spokes on the same side until the rim is true. For severe bends, apply gentle pressure to the rim with your hands or a rubber mallet to reshape it before making precise spokes adjustments.

Why does the bike tire keep coming off the rim?

The bike tire keeps coming off the rim because there might be a mismatch between the tire and rim size, incorrect tire installation, damaged or stretched tire bead, or excessive tire pressure. Ensuring the tire and rim are compatible, properly seated, and inflated within recommended pressure limits can prevent this issue.

Why does the bike tire leak air around the rim?

The bike tire leaks air around the rim because the tire bead is not properly seated against the rim, there might be damage or wear to the tire bead or rim, or the rim tape might be misaligned or damaged, causing an incomplete seal. Ensuring the tire is correctly installed, checking for any damage, and properly aligning or replacing the rim tape can help prevent air leaks.

Can alloy bike rims be fixed?

Yes, alloy bike rims can be fixed because minor bends or wobbles can often be straightened using spoke adjustments with a spoke wrench and a truing stand; but significant damage such as cracks or severe warping typically requires rim replacement as it compromises the structural integrity and safety of the wheel.

Can aluminum bike rims be straightened?

Yes, aluminum bike rims can be straightened because minor bends and wobbles can be corrected by adjusting the spoke tension with a spoke wrench and using a truing stand; but severe bends or cracks may compromise the rim’s structural integrity, making replacement a safer option.

How to buy a bike rim?

To buy a bike rim, consider factors such as the type of bike, rim material, and size compatibility. You can purchase bike rims from various sources, both online and offline, to find the best fit for your needs and budget. Here are the options for purchasing bike rims:

- Online Retailers: Websites like Amazon, eBay, and specialized cycling stores like Chain Reaction Cycles and Jenson USA offer a wide range of bike rims. They provide detailed product descriptions and customer reviews to help you make an informed decision.

- Local Bike Shops: Visit your local bike shop for personalized advice and immediate access to a selection of rims. Bike shop staff can help ensure you choose the correct rim for your bike and riding style.

- Distributors: Some bike part and equipment distributors offer rims directly to consumers. Check if local or regional distributors have a sales option for individual customers.

- Manufacturer Direct: Some manufacturers sell directly to consumers through their websites or customer service channels. This can be an excellent way to ensure you get authentic, high-quality rims.

- Second-Hand Markets: Websites like Craigslist, Facebook Marketplace, and dedicated cycling forums often have second-hand rims available. Ensure the rims are in good condition and compatible with your bike before purchasing.

To buy a bike rim, consider your specific requirements and the type of source that best fits your needs. Whether purchasing online for convenience, visiting a local shop for expert advice, or exploring second-hand options for cost savings, make sure to verify the rim’s compatibility and quality before finalizing your purchase.

How do you put spokes on a bike rim?

To put spokes on a bike rim, start by inserting the spokes through the hub flange and threading them through the spoke holes in the rim, following a specific lacing pattern (such as cross or radial), then secure each spoke with a nipple and progressively tighten them using a spoke wrench while ensuring the rim remains true and evenly tensioned.

How do you put a bike tire on a rim?

To put a bike tire on a rim, first insert one side of the tire bead into the rim, then place the inner tube inside the tire if applicable, slightly inflate it to give it shape, and finally work the second bead over the rim edge using your hands or a tire lever, ensuring the tire is evenly seated and the tube is not pinched.

How do you remove the bike tire from the rim?

To remove the bike tire from the rim, deflate the tire completely, then use a tire lever to pry one side of the tire bead over the rim edge, working your way around the rim until the tire is free on one side, and finally pull the tire and inner tube off the rim.

Do you need bike rim tape?

Yes, you need bike rim tape because it protects the inner tube from being punctured by the spoke holes or any sharp edges inside the rim, ensuring a smooth surface for the tube to rest against and preventing flats.

How important is bike rim tape?

Bike rim tape is important because it prevents the inner tube from being punctured by spoke holes and sharp edges inside the rim, ensuring a smooth surface that helps avoid flats and maintains tire pressure.

Do road tires fit mountain bike rims?

No, road tires do not fit mountain bike rims because mountain bike rims are typically wider and designed for larger, wider tires with different bead diameters and pressure requirements, making them incompatible with the narrower and differently shaped road tires.

Bike rim brands

When selecting bike rims, choosing a reputable brand known for quality, performance, and durability is essential. Here are some top bike rim brands and a brief explanation of their features:

- Bontrager Bike Rims: Bontrager rims are known for their lightweight aluminum and carbon fiber construction, offering excellent performance and durability across road, mountain, and gravel bikes.

- DT Swiss Mountain Bike Rims: DT Swiss is renowned for its high-performance mountain bike rims, featuring robust aluminum and carbon options designed for strength, lightweight, and reliability in tough terrain.

- Mongoose Bike with Rims: Mongoose offers affordable and durable rims primarily for BMX and mountain bikes, focusing on strength and stability for extreme riding conditions.

- Reynolds Bike Rims: Reynolds rims are high-end, and performance-focused, utilizing advanced carbon fiber technology to provide lightweight, aerodynamic, and stiff options for road and mountain bikes.

- Easton Bike Rims: Easton rims are known for their innovative materials and design, offering a range of aluminum and carbon fiber rims that excel in performance and reliability for both road and mountain biking.

- ENVE Bike Rims: ENVE is a premium bike brand offering top-tier carbon fiber rims, known for their exceptional stiffness, lightweight, and aerodynamic performance, catering to high-end road and mountain bike markets.

- Mavic Road Bike Rims: Mavic rims are iconic in the cycling world, known for their durable and lightweight aluminum and carbon options that provide excellent performance and reliability for road cycling.

- Shimano Bike Rims: Shimano rims are recognized for their quality and integration with Shimano components, offering a range of reliable and performance-oriented aluminum and carbon rims for various cycling disciplines.

- Specialized Bike Rims: Specialized offers a variety of rims that emphasize innovation and performance, featuring both aluminum and carbon options tailored for road, mountain, and gravel biking.

- Trek Bike Rims: Trek provides high-quality rims that focus on performance and durability, with options in both aluminum and carbon fiber, catering to a wide range of cycling needs, from road to mountain biking.

Bike rim manufacturers

Here is a list of 10 bike rim manufacturers, their countries and regions.

| Manufacturer | Country/Region |

| DT Swiss | Switzerland |

| ICAN | China |

| Mavic | France |

| ENVE | USA |

| Reynolds | USA |

| Easton | USA |

| Bontrager | USA |

| Shimano | Japan |

| Specialized | USA |

| Ritchey | USA |

How much does a bike rim cost?

A bike rim’s cost varies widely depending on the material, manufacturing process, brand, and specific features. Here’s the typical price range for carbon and aluminum bike rims:

Aluminum Bike Rim: $30 – $200

Carbon Bike Rim: $300 – $2,000

Factors Affecting Bike Rim Costs as listed below.

- Material: Carbon fiber is more expensive than aluminum.

- Manufacturing Process: Carbon rims require more labor-intensive processes.

- Brand Reputation: Well-known brands often charge a premium.

- Performance Features: Advanced features can increase the cost.

- Intended Use: Rims for high-performance applications tend to be more expensive.

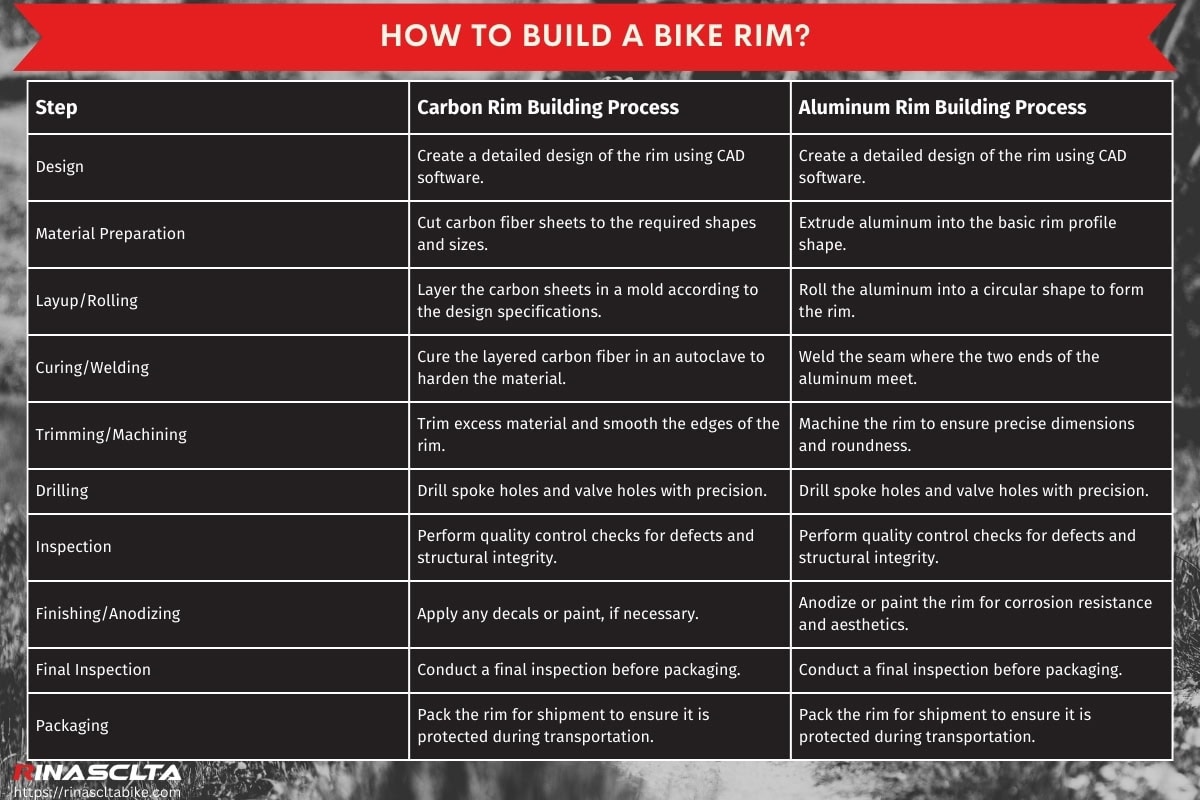

How to build a bike rim?

Building a bike rim involves a series of manufacturing processes that differ for bike rim materials like carbon and aluminum rims. Here are the steps involved in manufacturing each type of rim.

| Step | Carbon Rim Building Process | Aluminum Rim Building Process |

| Design | Create a detailed design of the rim using CAD software. | Create a detailed design of the rim using CAD software. |

| Material Preparation | Cut carbon fiber sheets to the required shapes and sizes. | Extrude aluminum into the basic rim profile shape. |

| Layup/Rolling | Layer the carbon sheets in a mold according to the design specifications. | Roll the aluminum into a circular shape to form the rim. |

| Curing/Welding | Cure the layered carbon fiber in an autoclave to harden the material. | Weld the seam where the two ends of the aluminum meet. |

| Trimming/Machining | Trim excess material and smooth the edges of the rim. | Machine the rim to ensure precise dimensions and roundness. |

| Drilling | Drill spoke holes and valve holes with precision. | Drill spoke holes and valve holes with precision. |

| Inspection | Perform quality control checks for defects and structural integrity. | Perform quality control checks for defects and structural integrity. |

| Finishing/Anodizing | Apply any decals or paint, if necessary. | Anodize or paint the rim for corrosion resistance and aesthetics. |

| Final Inspection | Conduct a final inspection before packaging. | Conduct a final inspection before packaging. |

| Packaging | Pack the rim for shipment to ensure it is protected during transportation. | Pack the rim for shipment to ensure it is protected during transportation. |